100 | CONCRETO & Construções | Ed. 91 | Jul – Set • 2018

(less than 5%) could present a

lower mechanical strength. On the

other hand, 95% must present a

compressive strength at 28 days

above the lower limit. Then, this

compressive strength lower limit is

given by the concrete class given in

Table 1.

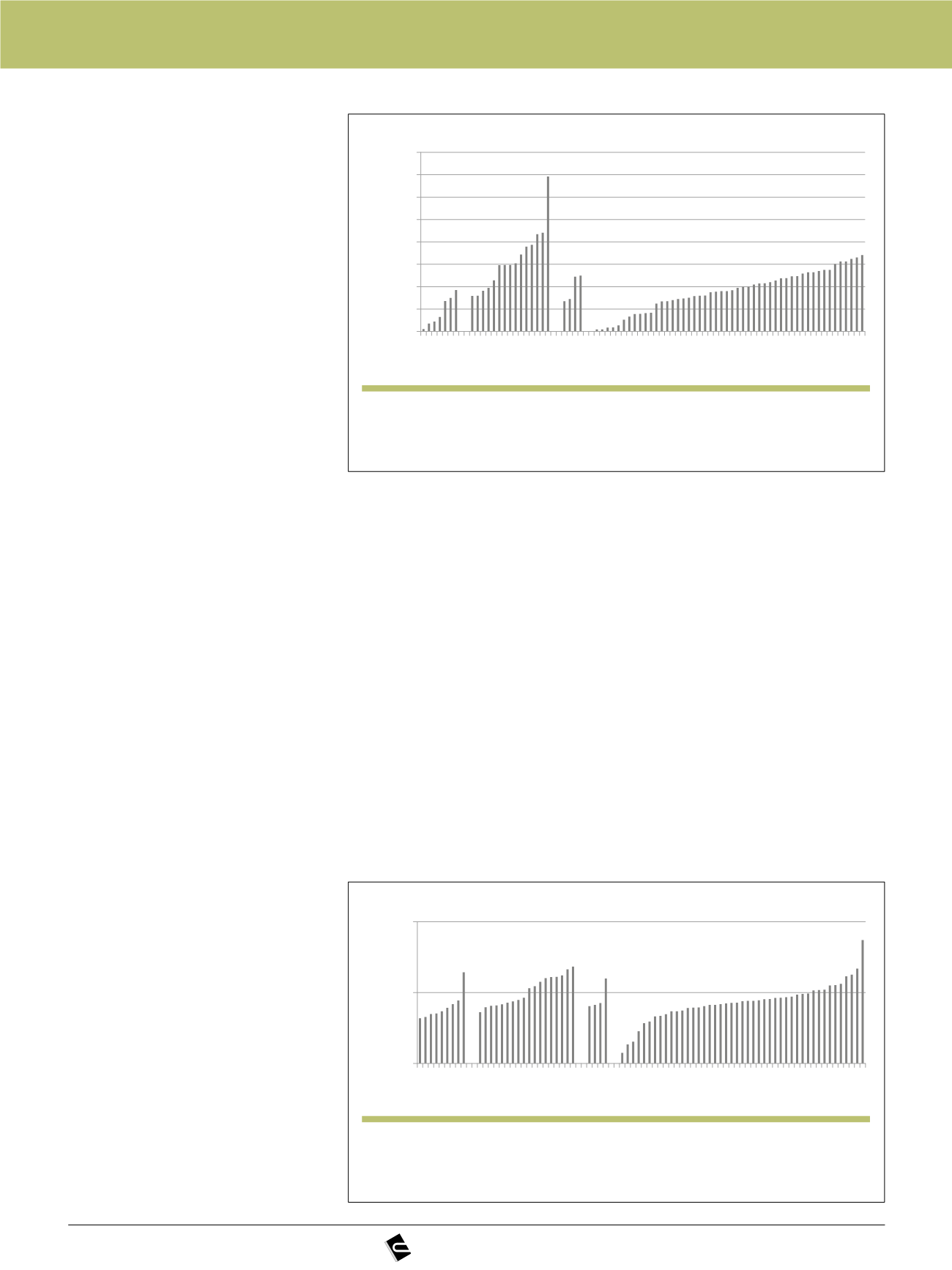

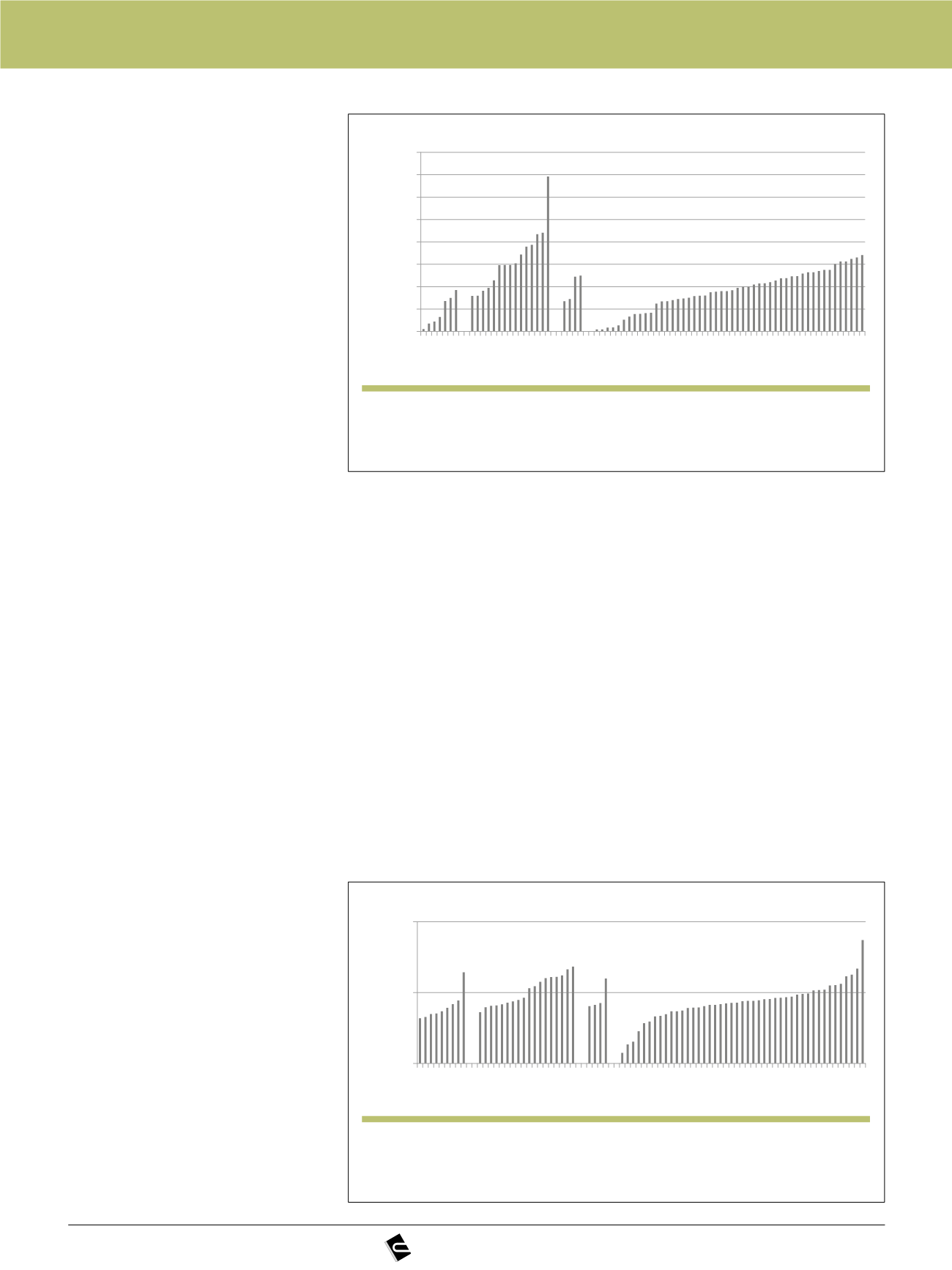

As expected, carbonation rate

and resistivity results also showed

a wide range of values (Figs. 4 and

5). The main difference between

these two parameters and the

28-days

compressive

strength

is that for these two parameters

there are not defined yet specified

values with statistical significance.

Consequently, a new approach for

these two properties is proposed in

a similar way to that followed for the

compressive strength. Therefore,

threshold values should be defined

in order to be able to assess the

compliance of the service life

defined in the design step, which is

related to the concrete cover depth

prescribed for each exposure class.

4. DISCUSSION

In order to analyze more in

detail the possibility to establish a

limiting value for the carbonation

rate, the probabilities of failure and

corresponding reliability index are

calculated from the minimum and

maximum values of the carbonation

rates. The results for 50 and 100

years of nominal service life are

given in Fig. 6. Therefore, it can be

deduced that the minimum values of

carbonation rate give excessive safe

structures (very positive

β

values)

and the maximum values however,

very unsafe (very negative) ones.

Logically, changing the cover depth

will change dramatically the level of

safety because it has to be taken

into account that the exercise is

made with a fixed value of the cover

depth (Table 1). For example, in the

case of XC4 exposure class, the

maximum value of the carbonation

rate measured is 6 mm/year

0.5

, which

will have a

β

= 0 if a cover depth of

around 42 mm is used instead of 30

mm as made in the exercise of Fig.

6. Another example is that a

β

= 1.12

(12% of depassivation probability)

can be obtained with a cover depth

of 60 mm. Then, the level of safety of

the concrete mixes by each exposure

class can be fixed with flexibility by

the cover depth, after knowing their

carbonation rates.

Another aspect to question is

that in fib MC 2010 assimilates steel

depassivation to a serviceability

limit state indicating a

β

value of 1.3,

equivalent to 10% failure probability,

which on the light of present results

may be too conservative. That is,

the probability of depassivation

should not be a general value but a

value which could take into account

the importance of the structure and

the consequences of failure. In the

u

Figure 4

Concrete carbonation. They are ranked by carbonation exposure class

according to the European standard EN 206

0,00

2,00

4,00

6,00

8,00

10,00

12,00

14,00

16,00

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 61 64 67 70 73 76 79 82

VCO2 (mm/year^0.5)

concretes

Ranked by Exp. class XC

XC1 XC2 XC3 XC4

u

Figure 5

Concrete resistivity. They are ranked by carbonation exposure class

according to the European standard EN 206

10

100

1000

Resistivity (ohm.m)

concretes

Ranking XC

XC1 XC2 XC3 XC4

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 61 64 67 70 73 76 79 82