CONCRETO & Construções | Ed. 91 | Jul – Set • 2018 | 99

were submitted to natural carbonation

according to the test method explained

below and the 28 days compressive

strength was determined according to

the EN 12390:2009: Testing hardened

concrete. Part 3: Compressive

strength of test specimens [11].

2.2 Natural carbonation

testing

Natural carbonation testing was

performed following the procedure

described in the European Technical

Specification CEN/TS 12390–10:

Testing hardened concrete – Part

10: Determination of the relative

carbonation resistance of the

concrete [12].

The

carbonation

exposure

classes (XC) considered in the

present paper are the ones described

in the European concrete standard

EN 206 [9] and given in Table 1. This

table shows the deemed-to-satisfy

rules of EN 206 for carbonation.

2.3 Concrete resistivity

Resistivity measurements were

performed following the Spanish

standards UNE 83988-1:2008 [13]

and UNE 83988-2:2014 [14].

2.4 Reliability calculations

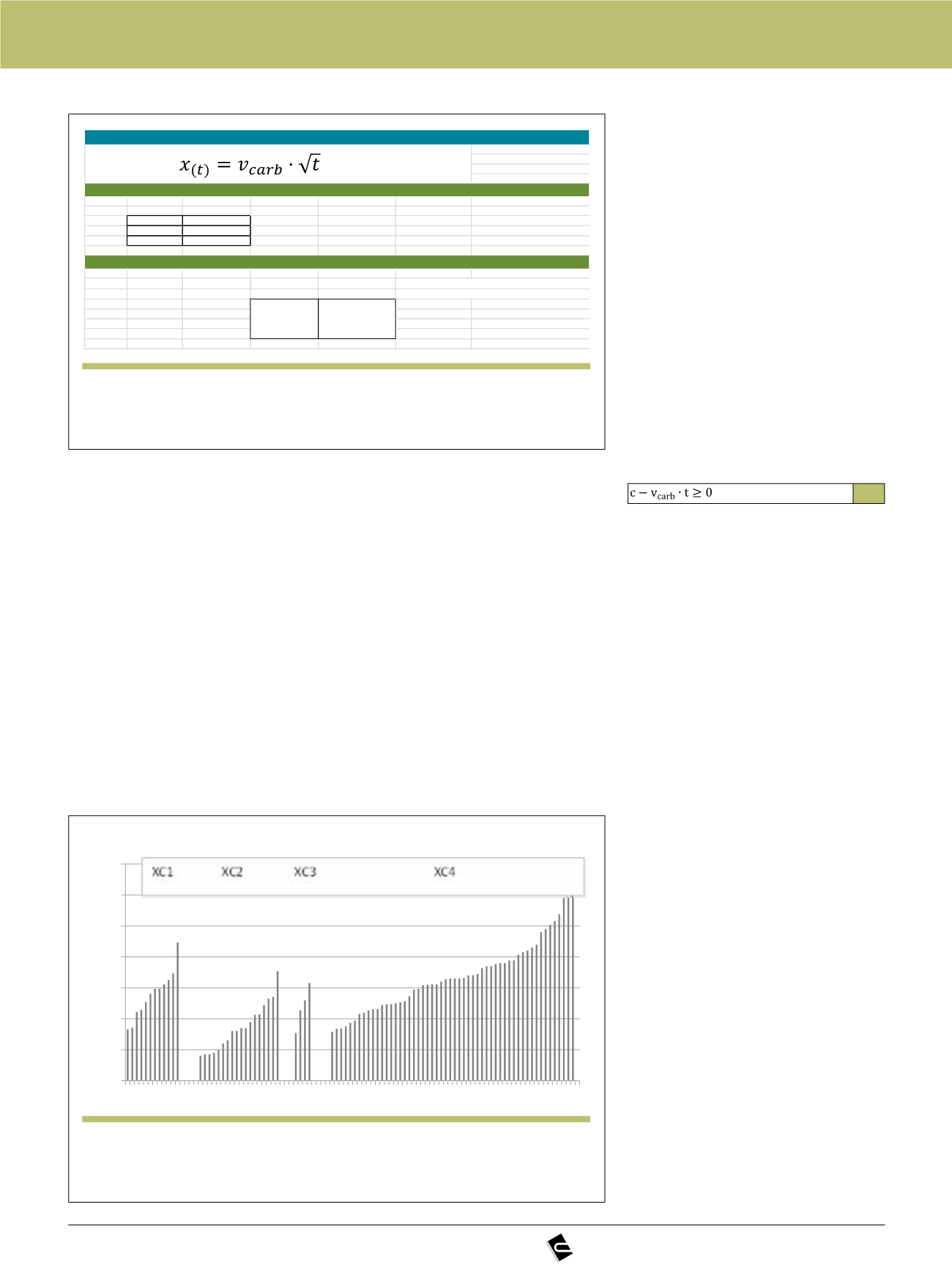

Equation (1) is considered as

the assumed limit state function for

carbonation, where c is the cover

depth (mm), v

carb

is the carbonation

rate (mm/year

0.5

) and t is the time

(years).

1

Calculations were developed on

a excel spreadsheet by using the

well-known Montecarlo simulation

as shown in Fig. 2. This procedure

enables the calculation of the

probability of failure, with regard

to the steel depassivation, and the

reliability index “

β

”.

3. RESULTS

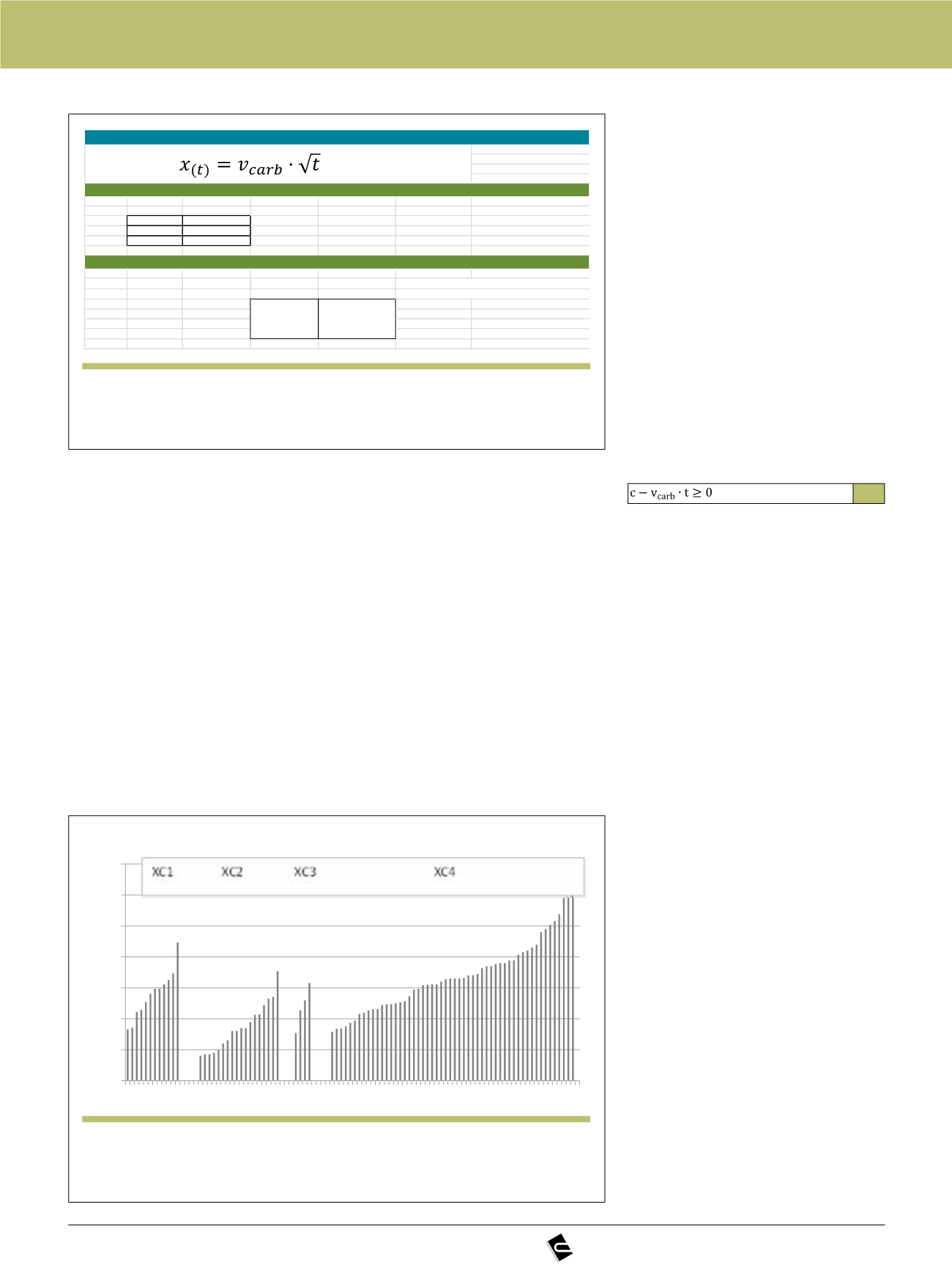

Compressive strength at 28

days, carbonation rate and resistivity

were determined for all the concrete

mixes. Then, they were ranked

considering the exposure classes

presented in Table 1 in order to get

a clear classification of concretes

fulfilling

the

deemed-to-satisfy

rules prescribed by the European

standard EN 206 for carbonation.

The three properties showed the

same trend. Given that, the values

increased from a minimum to a

maximum. Compressive strength

at 28 days (Fig. 3) is presented

with their statistical significance

with a probability equal or higher of

95%. Therefore, this requirement

means that some concrete mixes

u

Figure 2

Excel spreadsheet showing Montecarlo simulation for the calculation

of the probability of failure according to Eq. (1)

MODELO DE CARBONATACIÓN √

t

PARÁMETROS DE ENTRADA

Parámetro

μ

σ

COV

Unidad

Tipo de variable Descripción

v_carb

10,51

3,153

0,30

mm/año

Normal

Velocidad de carbonatación

c

25

3,75

0,15

mm

Lognormal

Recubrimiento

t

50

-

-

años

Constante

Vida útil de diseño

RESULTADOS OBTENIDOS

Número de simulaciones MC: 10.000

Función profundidad decarbonatación

74,06

PROMEDIO

22,24

DESV. ESTÁNDAR

0,30

COV

-2,18

ÍNDICEFIABILIDAD

Pf

98,7%

u

Figure 3

Concrete 28-days compressive strength. They are ranked by carbonation

exposure class according to the European standard EN 206

10

20

30

40

50

60

70

80

1

5

9

13

17

21

25

29

33

37

41

45

49

53

57

61

65

69

73

77

81

85

89

93

97

Mechanical stregth (Mpa)

Exposure class XC