CONCRETO & Construções | Ed. 91 | Jul – Set • 2018 | 101

u

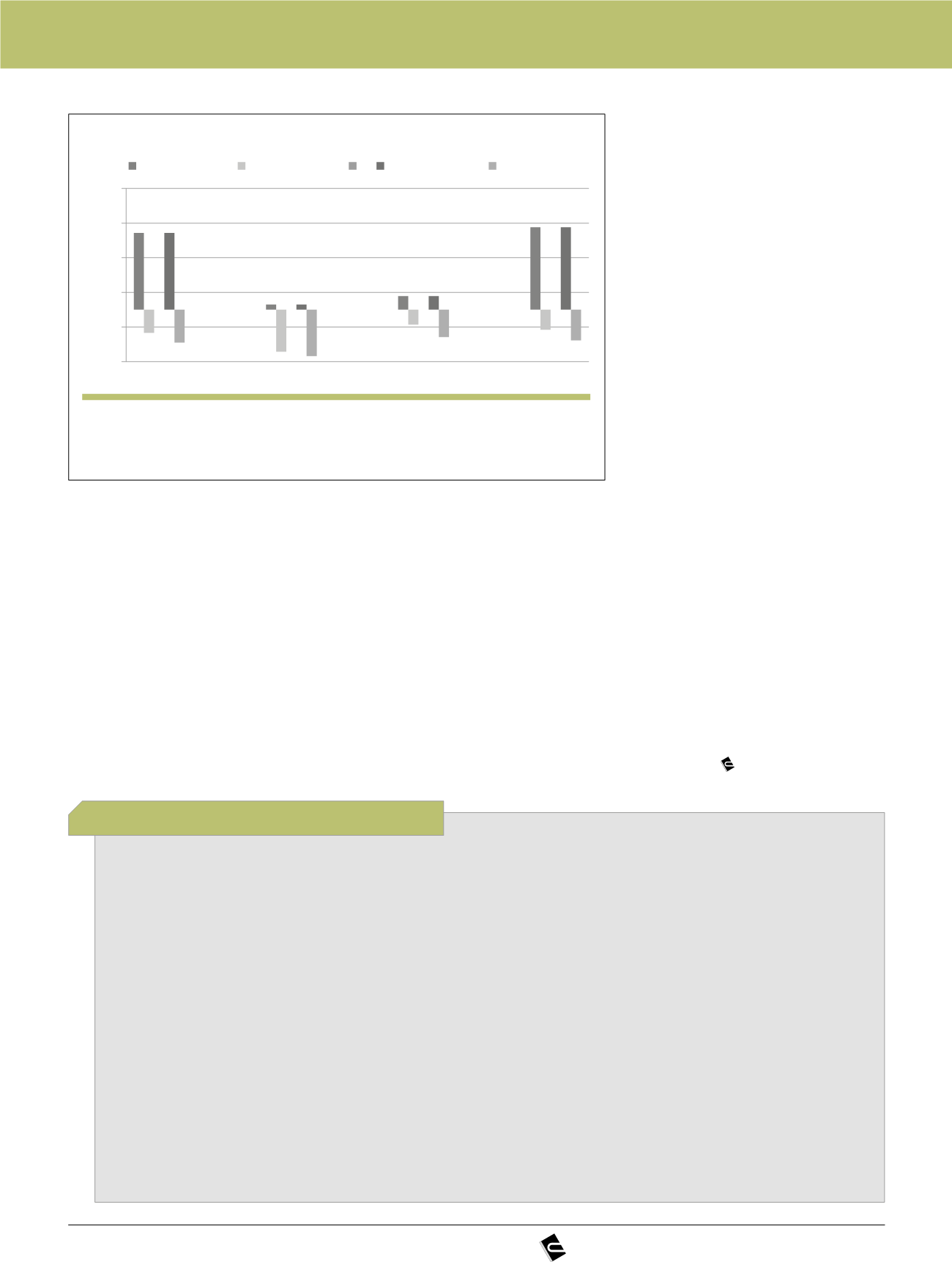

Figure 6

Reliability index

β

for the minimum and maximum values of the carbonation rate

of the concretes ranked in figure 3 for nominal service life of 50 and 100 years

-3

-1

1

3

5

7

Beta value

XC1 XC2 XC3 XC4

Exposure class XC

Beta 50 y mim Beta, 50 y max

beta 100 y min beta 100 y max

meantime that this limiting value is

rationally selected, it can be taken

as an reference the deterministic

value (the mean one), which

corresponds to a failure probability

of 50% (

β

=0).

5. CONCLUSIONS

The main conclusions drawn up

from present paper are:

u

The failure (steel depassivation)

probability of standard concretes

may vary with respect to

carbonation within those fulfilling

the prescriptive rules of the mix

proportioning for each exposure

class. This also happens with the

mechanical strength.

u

In the case of the strength a

limiting value for exposure class

is established which is not still

agreed with statistical significance

for the carbonation rates or other

concrete properties.

u

In the case of the carbonation

rate, the failure probability

depends on the cover depth

as indicated in the limit state

function (Eq. 1).

u

Providing that this limiting value of

the carbonation rate should take

into account the importance of the

structure and the consequences

of failure, a fixed value seems

not logical. In the meantime a

more statistically based value

is decided for standards, the

deterministic, mean value (

β

=0)

can be a starting point.

6. ACKNOWLEDGEMENTS

The authors thank to CALIDUR

project for providing the experimental

data, in particular to Renata

D’Andrea. They are also grateful the

funding from the Technical Building

Code of Spain. Finally, they also

thank to the members of the fib

Commission 8 TG8.3 for the fruitful

discussions.

[1] Papadakis, V.G., Vayenas, C.G., Fardis, M.N., Fundamental modeling and experimental investigation of concrete carbonation, ACI Mater J 88 (1991), 363–373

[2] Parrott, L.J., Study of carbonation-induced corrosion. Mag Concr Res, 46(166) (1994), 23-28

[3] Parrott, L.J., Damage caused by carbonation of reinforced concrete. Mater Struct, 23(3) (1990), 230-234

[4] Sanjuán, M.A., Andrade, C., Cheyrezy, M., Concrete carbonation tests in natural and accelerated conditions, Adv Cem Res 15(4) (2003), 171-180

[5] CEB-FIP, The fib Model Code for Concrete Structures 2010, Ernst and Sohn, Germany (2012)

[6] EHE-08, Spanish Code for calculation of Structural concrete, Royal Decree 1247/2008, Ministerio de Fomento, Spain (2008)

[7] EN 1992-1-1, Eurocode 2; Design of concrete structures Part 1-1: General rules and rules for buildings, European Committee for Standardization, CEN,

Belgium (2010)

[8] The fib (International Federation for Structural Concrete), TG 5.6, Model Code for Service Life Design, bulletin 34, Lausanne, Switzerland (2006)

[9] EN 206-1+A1, Concrete - Part 1: Specification, performance, production and conformity, European Committee for Standardization, CEN, Belgium (2016)

[10] Gonzalez, J.A., Algaba, S., Andrade, C., Corrosion of reinforcing bars in carbonated concrete, Brit Corr J, 15(3) (1980) 135-139

[11] EN 12390-3, Testing hardened concrete. Part 3: Compressive strength of test specimens, European Committee for Standardization, CEN, Belgium (2009)

[12] CEN/TS 123903-10, Testing hardened concrete – Part 10: Determination of the relative carbonation resistance of the concrete, European Committee for

Standardization, CEN, Belgium (2010)

[13] UNE 83988-1, Durabilidad del hormigón. Métodos de ensayo. Determinación de la resistividad eléctrica. Parte 1: Método directo (método de referencia),Asociación

Española de Normalización, UNE, Spain (2008)

[14] UNE 83988-2, Durabilidad del hormigón. Métodos de ensayo. Determinación de la resistividad eléctrica. Parte 2: Método de las cuatro puntas o de Wenner,

Asociación Española de Normalización, UNE, Spain (2014)

u

R E F E R Ê N C I A S B I B L I O G R Á F I C A S