98 | CONCRETO & Construções | Ed. 91 | Jul – Set • 2018

Structural Concrete Code [6] in

2008. However, the weak point of

these models is the lack of calibration

beyond 30 years ago, when the

service life models begun to be

proposed. Therefore, the precision

of their predictions sometimes is

not good enough. Eurocode 2 on

concrete Structures [7] is being

revised by the European technical

committee on standardization CEN/

TC 250. This revision has promoted

the assessment of the most

common durability models. Also,

the fib Commission 8 on Durability

is undertaking some calibration

exercises within this context.

In addition to the probability of

failure, another commonly used

probabilistic parameter of safety is

the reliability index. Then, mentioned

assessment could be performed

by calculating the reliability index

with regard to the cover depth

defined in each exposure class

through the use of carbonation

models [8]. Thus, from the deemed-

to-satisfy-rules prescribed in EN

206 [9] carbonation rates were

ascribed and the reliability index

with respect to the reinforcement

cover is calculated. However, this

calculation lacks of proper testing

of the concretes because the rate-

determining input parameters of

the carbonation models were not

tested, but estimated. Given that,

a single value of carbonation rate

is assumed for each prescription

of water/cement ratio and cement

content. Therefore, this theoretical

approach could be conservative but

far from the actual performance [10].

As result, carbonation rate results

can be obtained in concretes with

the same water/cement ratio and

cement content.

In present paper the calibration

of deemed-to satisfy-rules is made

with a really tested set of more

than 60 types of concrete mixes

made in some locations all around

of Spain following the European

standards. From the carbonation

results, a mathematical analysis was

performed taking into account the

prescribed minimum concrete cover

in order to calculate the reliability

index and then, the safety level

offered by the current prescriptive

rules given by the European standard

EN 206 “concrete” [9].

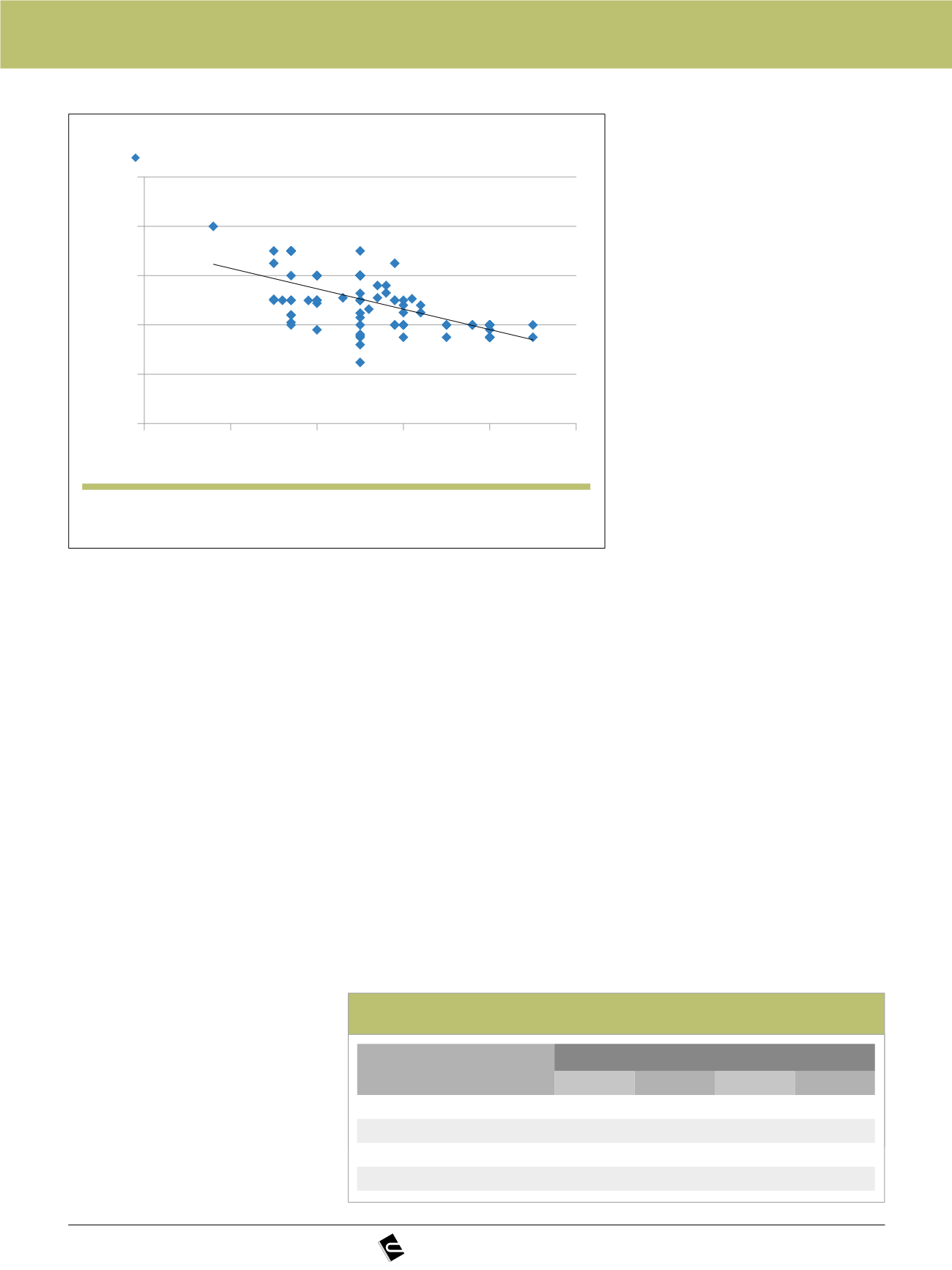

2. EXPERIMENTAL

2.1 Concrete design

Some concrete mixes were made

in different ready-mix concrete plant

and research laboratories located

in several places all around Spain.

The cement content for the concrete

mixes (Fig. 1) was ranged between

275 kg and 500 kg, whereas the

water/cement ratio from 0.37 to 0.65.

These two parameters covered all the

concrete design mixes employed in

the country. All the concretes were

cured during 28 days in standardized

conditions (wet curing). Then, they

u

Figure 1

Relation between cement content and water/cement ratio of the concrete mixes

y = - 414,07x + 539,01

R² = 0,2862

100

200

300

400

500

600

0,2

0,3

0,4

0,5

0,6

0,7

3

Cement content (kg/m )

w/c ratio

Relation amount of cement – w/c ratio

relation amount of cement-w/c ratio – Linear (relation amount of cement-w/c ratio)

u

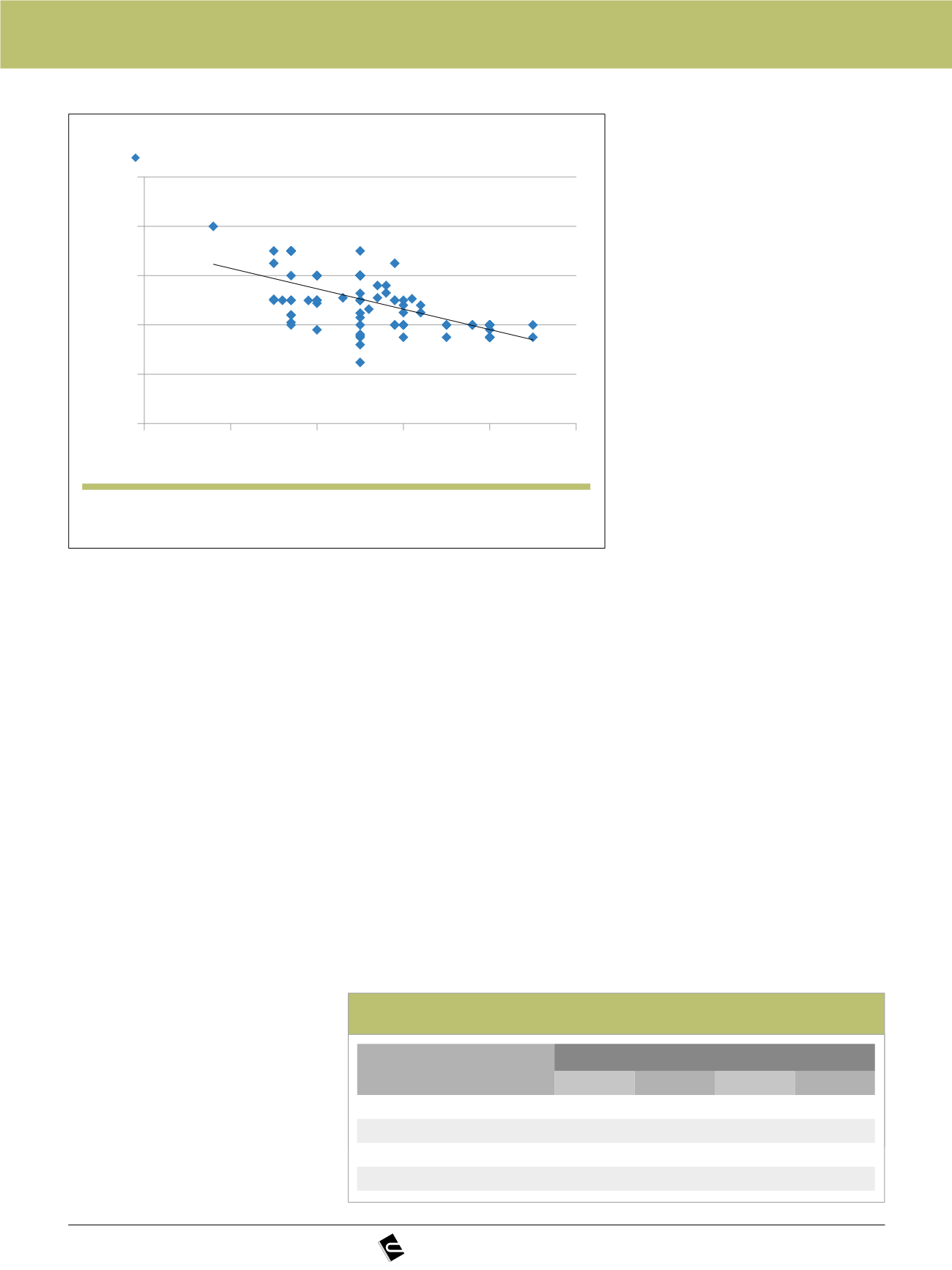

Table 1 – Exposure classes of EN 206 for carbonation

Parameter

Exposure class: carbonation

XC1

XC2

XC3

XC4

Maximum w/c ratio

0.65

0.60

0.55

0.50

Minimum cement content

260

280

280

300

Cover depth (for S4)

15

25

25

30

Compressive strength

C20/25

C25/30

C30/37

C30/37