CONCRETO & Construções | Ed. 93 | Jan – Mar • 2019 | 59

u

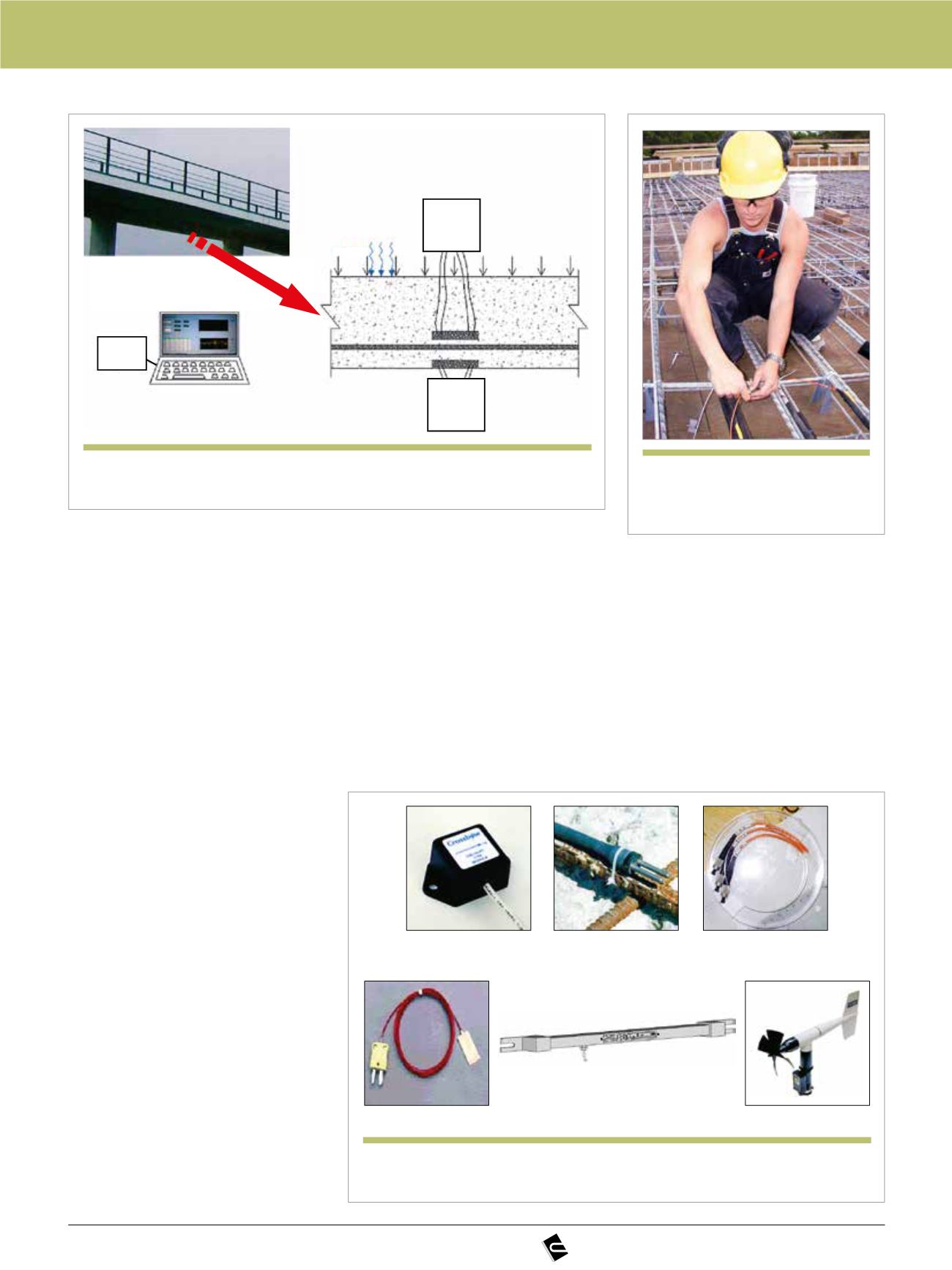

Figure 2

Schematic of data acquisition from a sensor Bottom

DAQ

System

Wireless

Sensing

Unit

Wireless

Sensing

Unit

Front

CI

of major rehabilitation or outright re-

placement. Not surprisingly, nearly

half of our construction activity is cur-

rently geared towards the repair and

strengthening of our infrastructure,

and as the infrastructure ages fur-

ther, this will place further demands

on our already stretched infrastruc-

ture budget.

One additional setback facing

our already worn out infrastruc-

ture is Global Warming. With atmo-

spheric CO

2

levels expected to ap-

proach 1000 ppm from their current

level of 600 ppm and atmospheric

temperatures expected to rise by

as much as 5.5

o

C, deterioration in

our concrete structures is only ex-

pected to accelerate. Higher CO

2

levels will cause much greater car-

bonation and corrosion and higher

temperatures will lead to greater

thermal stresses and shrinkage in-

duced cracking. All in all, one can

expect greater instances of struc-

tural failure and increased mainte-

nance costs in the future.

2. STRUCTURAL HEALTH

MONITORING (SHM)

The Johnson Commission, which

investigated the Laval collapse,

strongly urged the government to

make bridge and overpass health

monitoring an absolute priority. Un-

fortunately, the current tools in our

arsenal for bridge inspections and

health monitoring remain antiquated

and unable to accurately predict the

true condition of the structure (Fig. 4).

In particular, they are unable to pre-

dict deterioration both in steel (aris-

ing from corrosion) and in concrete

(arising from chemical and physical

attack including freeze-thaw, scaling

u

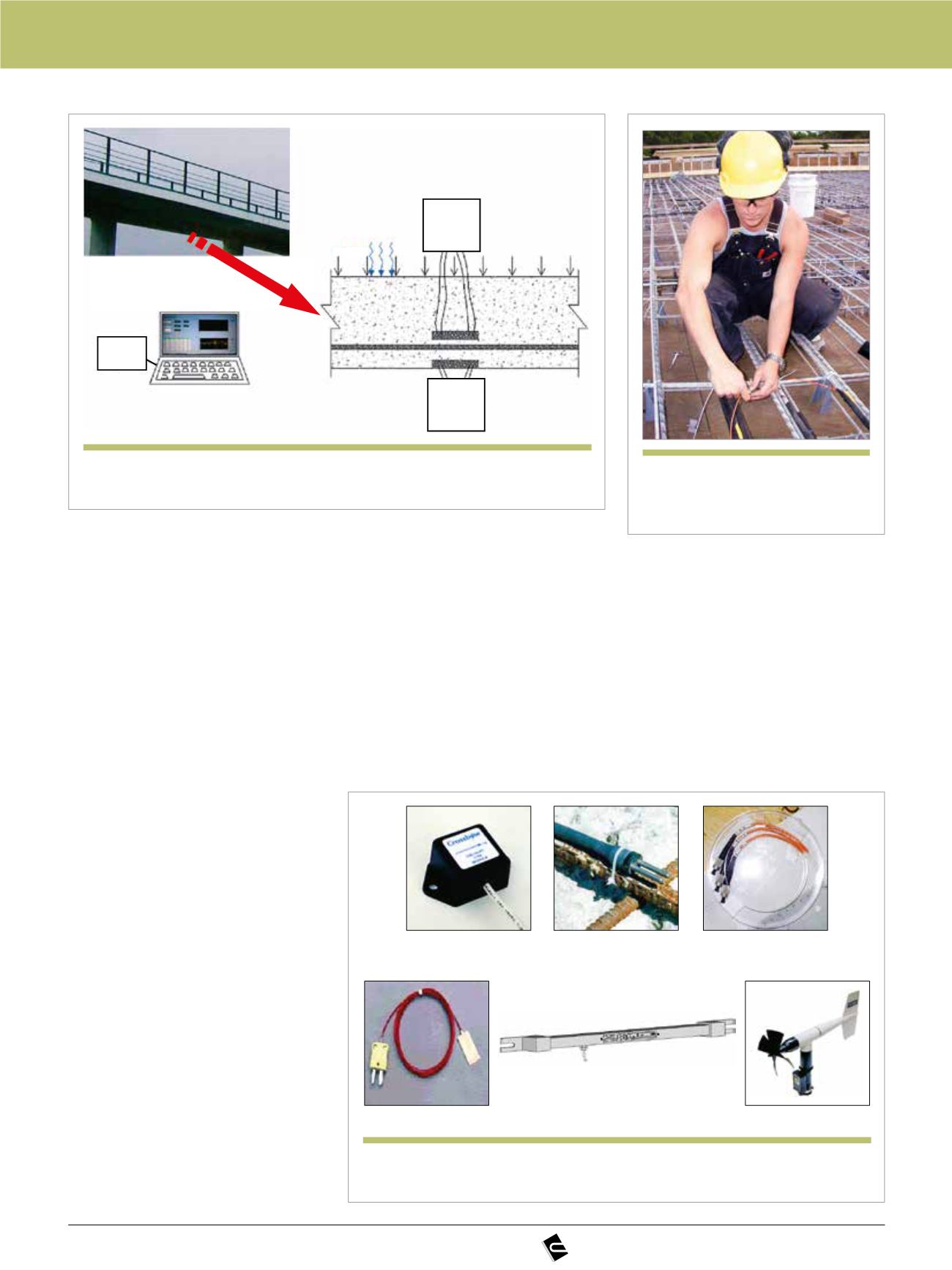

Figure 3

Installing a sensor

on a bridge deck

u

Figure 4

Sensors for concrete structures

Crossbow tri-axial

Thermocouple

Wind monitor

Tilt-Beam sensor

Corrosion sensor

Fibre-Optic sensor