60 | CONCRETO & Construções | Ed. 93 | Jan – Mar • 2019

and alkali-aggregate reaction (AAR)).

Current techniques are also unable

to predict damage in elements aris-

ing from loading, fatigue, acciden-

tal impact and unavoidable stress

concentrations.

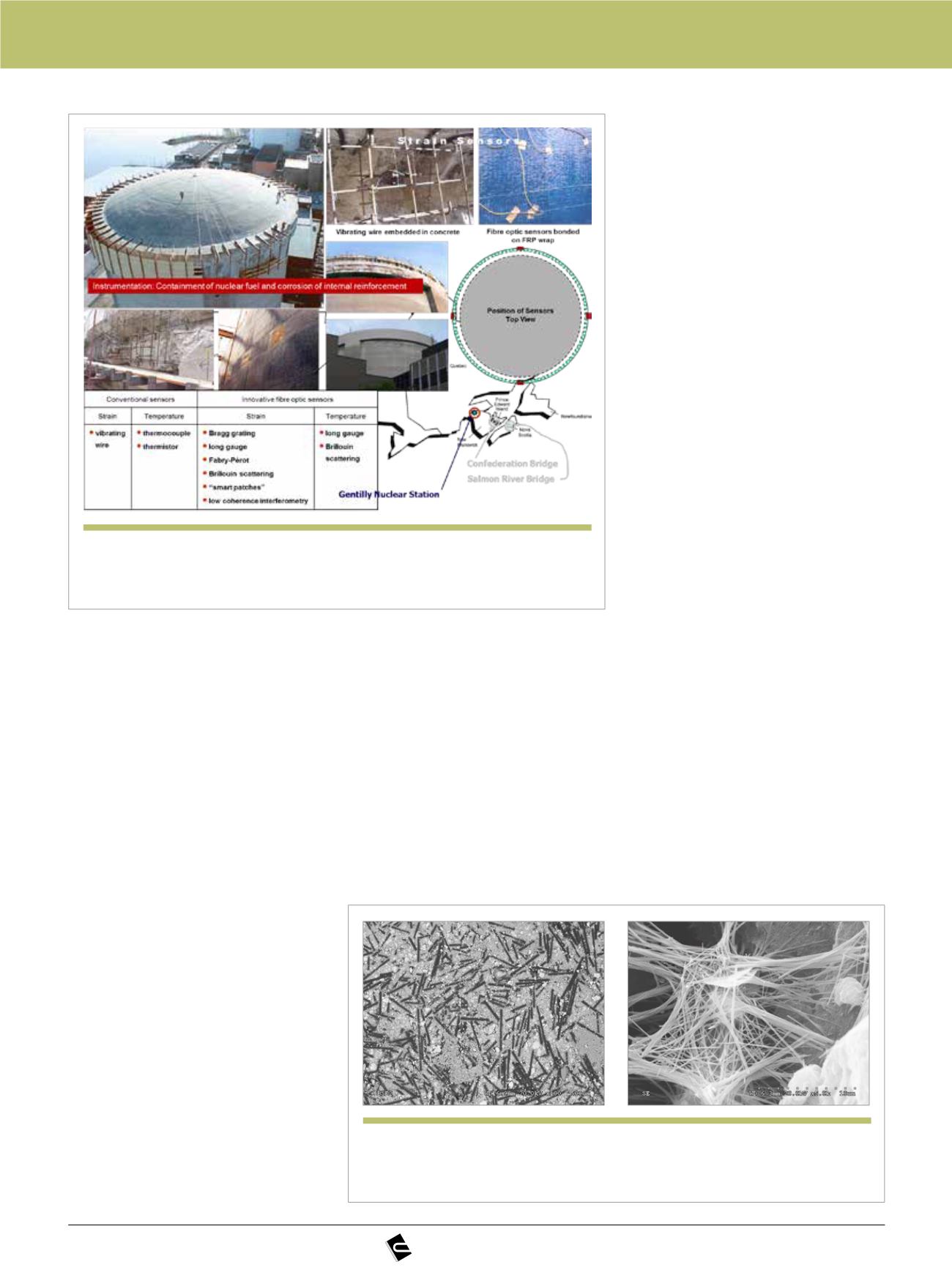

Structural health monitoring (SHM)

using fibre optic sensors (FOSs) stra-

tegically integrated into structural sys-

tems is part of an effective approach

towards infrastructure management.

The same has been studied and ap-

plied to numerous structures in Cana-

da (the Safe Bridge, near Duncan, BC,

for example, and the Gentilly Nuclear

Reactor in Quebec, see Fig. 5) and

abroad. Unfortunately, FOSs are pro-

hibitively expensive and are not able

to sense changes in the chemical en-

vironment in concrete that lead to du-

rability and deterioration concerns. A

number of novel sensors are now in

development.

3. CONCRETE USED

AS A SENSOR

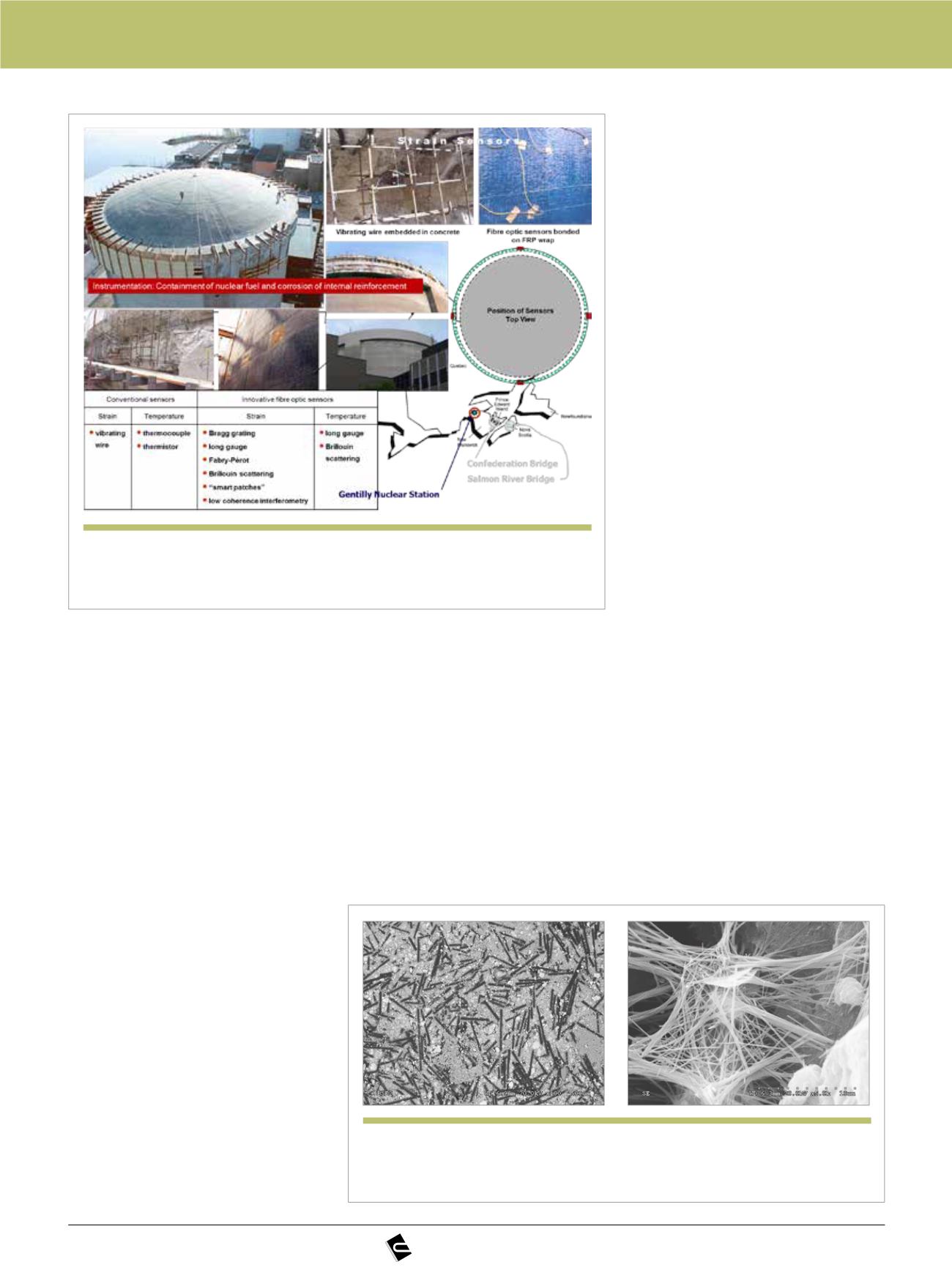

Recently, a new type of concrete

has been developed at the Univer-

sity of British Columbia (UBC) which

can not only sense changes in its

stress condition and temperature,

but also detect the presence of

cracking and other damaged states,

changes in the chemical environ-

ment, chloride content and onset

of steel corrosion, moisture content

and loss of strength. As opposed

to other sensors, their cementitious

nature allows them to be integrat-

ed better into the parent structure

where they develop a natural bond

and have similar physical and trans-

port properties (Fig. 6). When in-

stalled strategically as tiny sensors

in the structure, these elements can

interact wirelessly over the internet

and provide the engineer with con-

tinuous data on the overall health of

the structure they form part of (Fig.

8). These can easily be integrated in

both new and old structures and can

be interrogated continuously or peri-

odically depending on the need.

Concrete by nature is a poor con-

ductor of electricity and, hence, a poor

sensor. The only requirement for con-

crete to start sensing is that it should

be a good conductor of electricity and

must show a variation in its resistiv-

ity when the conditions are altered. A

detectable response may emerge as

a result of changes in the strain/stress

field (a property often called piezore-

sistivity, see Fig. 7) or to changes in

the chemical environment (a property

u

Figure 5

Sensors on Gentilly Nuclear Reactor in Quebec

(Courtesy: Professor, ISIS Canada)

u

Figure 6

Left: cement composite with carbon fibre at 100X magnification

Right: MWCNT bridging hydration products at 5000X magnification