CONCRETO & Construções | Ed. 93 | Jan – Mar • 2019 | 61

dubbed chemoresistivity). Concrete

developed at UBC has highly sensitive

responses to both stimuli.

In the past, attempts to en-

hance the electrical conductivity of

concrete have been limited to use

of conducting fibres (pitch or poly-

acrylonitrile-based carbon fibre,

for example). In the concrete de-

veloped at UBC, carbon fibres are

hybridized with multi-walled carbon

nano-tubes (MWCNT) that makes

the concrete extremely responsive

to stress and chemical changes. Im-

pedance Spectroscopy is then used

to separate the influences of various

stimuli. Comparisons with traditional

sensors indicate that the stress sen-

sitivity of the cementitious sensors

is two orders of magnitude greater.

There is unfortunately no traditional

chemical sensor available with which

to compare these.

The sensors developed can also

detect strength gain in concrete,

and can be used in precast plants

for arriving at decisions related to

form removal, transportation, cold

joints, etc.

In addition to sensing, numer-

ous novel applications for electri-

cally conductive concrete can be

envisaged; these include: electri-

cal grounding, lightning arresters,

self-heating bridge decks for de-

icing, electromagnetic interference

shielding and static-free computer

room floors.

4. CONCLUSIONS

Structural failures around the

world have indicated that our struc-

tures are deteriorating rapidly and

this has created a crisis of unprec-

edented proportions. Even a bigger

concern is that we have poor un-

derstanding of what condition our

structures are in, and where the crit-

ical locations of deterioration are. It

is imperative therefore that we install

sensors on both new and old struc-

tures so a real-time structural health

monitoring can be performed. Such

sensors can not only alert us of an

impending collapse and safe lives,

but can also provide very useful

data needed for decisions pertain-

ing to infrastructure management in-

cluding functional obsolesce, repair

and rehabilitation.

u

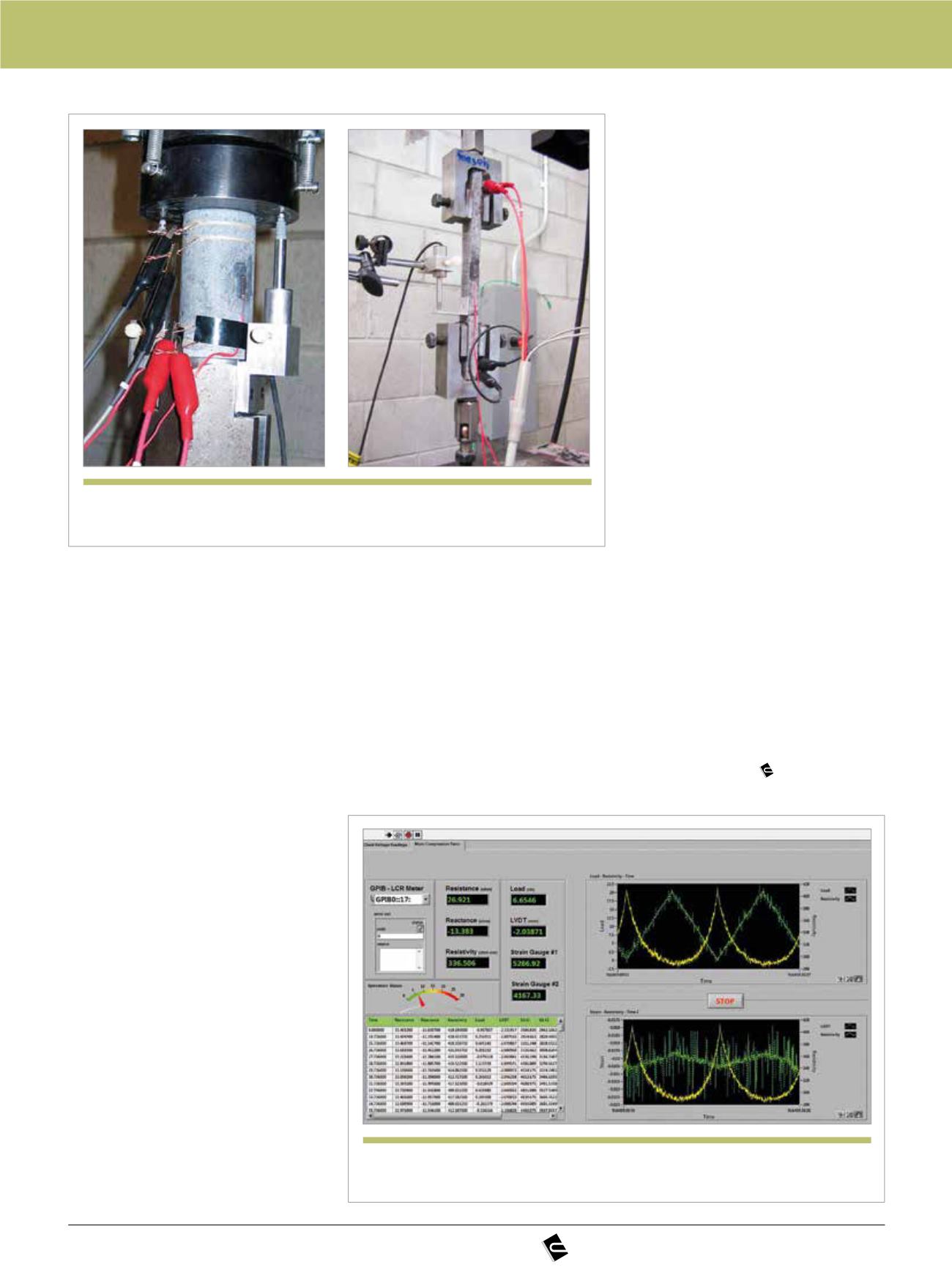

Figure 7

Smart concrete; Left: sensor in compression; Right: sensor in tension

u

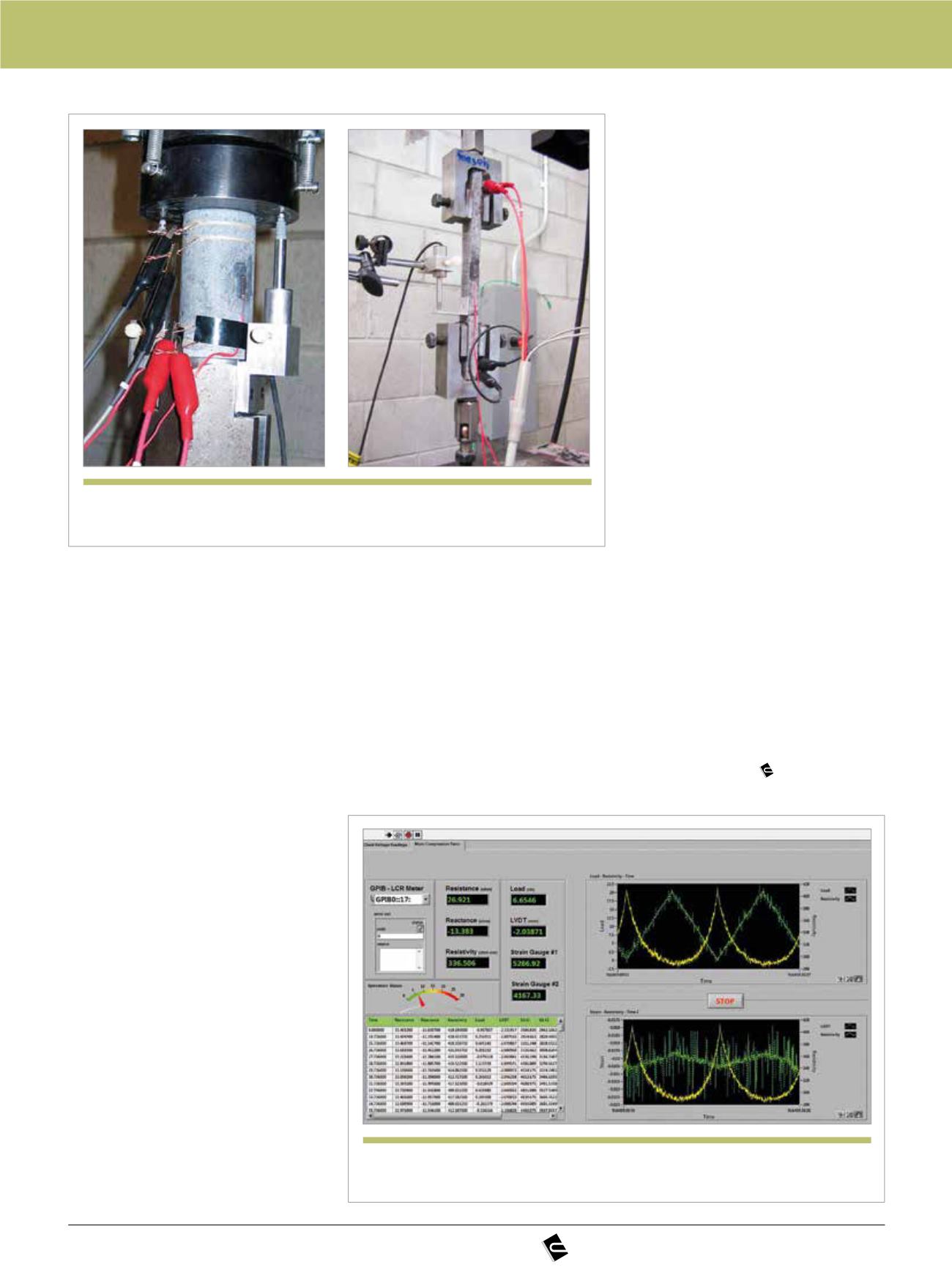

Figure 8

Sensor interface from a smart concrete used as a sensor