CONCRETO & Construções | 57

passenger cars and trucks.

With the Close Proximity Method

(CPX, ISO/CD 11819-2) it is chiefly

the tyre-pavement noise that is mea-

sured by attaching a microphone

close to the test tyre. These tyres

are usually mounted on an acous-

tically insulated trailer. The type of

test tyre that is used will obviously

play an important role in determining

the results.

In the United States, the On

Board Sound Intensity (OBSI) meth-

od is often used (Ref. 5), which is

somewhat comparable to the CPX.

Instead of sound pressure, however,

sound intensity is measured by us-

ing two microphones which are bet-

ter able to isolate the tyre-pavement

noise for separate measurement.

Since CPX and OBSI measure-

ments take place very close to the

tyre, they will result in high values of

noise levels. Obviously, those are

not the noise levels to which humans

are being exposed in real life. This

should be kept in mind when read-

ing the case studies, further on in

this paper.

3. BASIC RULES FOR

A QUIET PAVEMENT

The following factors have an in-

fluence on the tyre-pavement noise:

u

good smoothness of the road

with the absence of bumps or ir-

regularities in the surface (which

is also called “megatexture”);

u

a homogenous but non-sys-

tematic distribution of small ag-

gregates, up to 10mm on the

surface (which is considered as

“macrotexture”). The air is able

to escape between the gaps in

the aggregate. Important note:

a perfectly flat surface is not

low-noise;

u

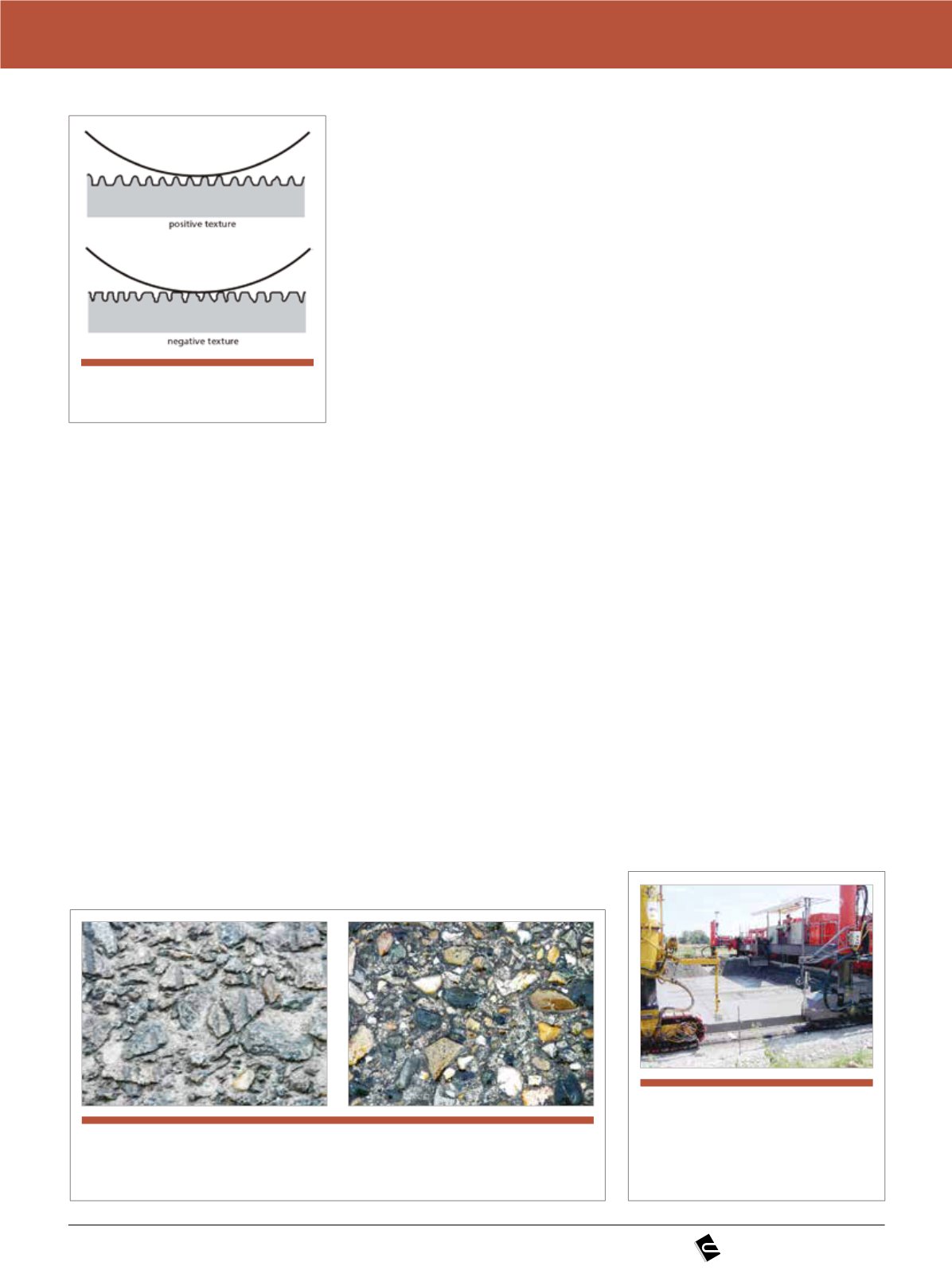

it is better to have a negative tex-

ture than a positive one (see Fig-

ure 4);

u

porosity: a maximum content

of empty space (up to 20% or

more), which enables sound to

be absorbed, insofar as the pores

remain open at the surface;

u

limited stiffness of the surface

layer.

In optimising a quiet pavement

surface, if possible, various fac-

tors should be taken into account

at once. Moreover, no concessions

should be made in the durability of

the pavement. In addition, a solu-

tion with long-term noise perfor-

mance should be preferred to sur-

faces deteriorating after few years.

Similar to wearing surfaces of po-

rous asphalt, it is possible to build

surfaces of porous (or very open)

concrete. By leaving out the sand

component in the composition, ac-

cessible gaps are created between

the coarse aggregates. In order to

achieve better adhesion between

the stones, polymers may be added.

Very open concrete is comparable

to very open asphalt: there is great

potential for noise reduction and

water-spray is eliminated. However,

there are also downsides: there is a

risk of clogging and the surface is

u

Figure 4

Positive vs. negative texture

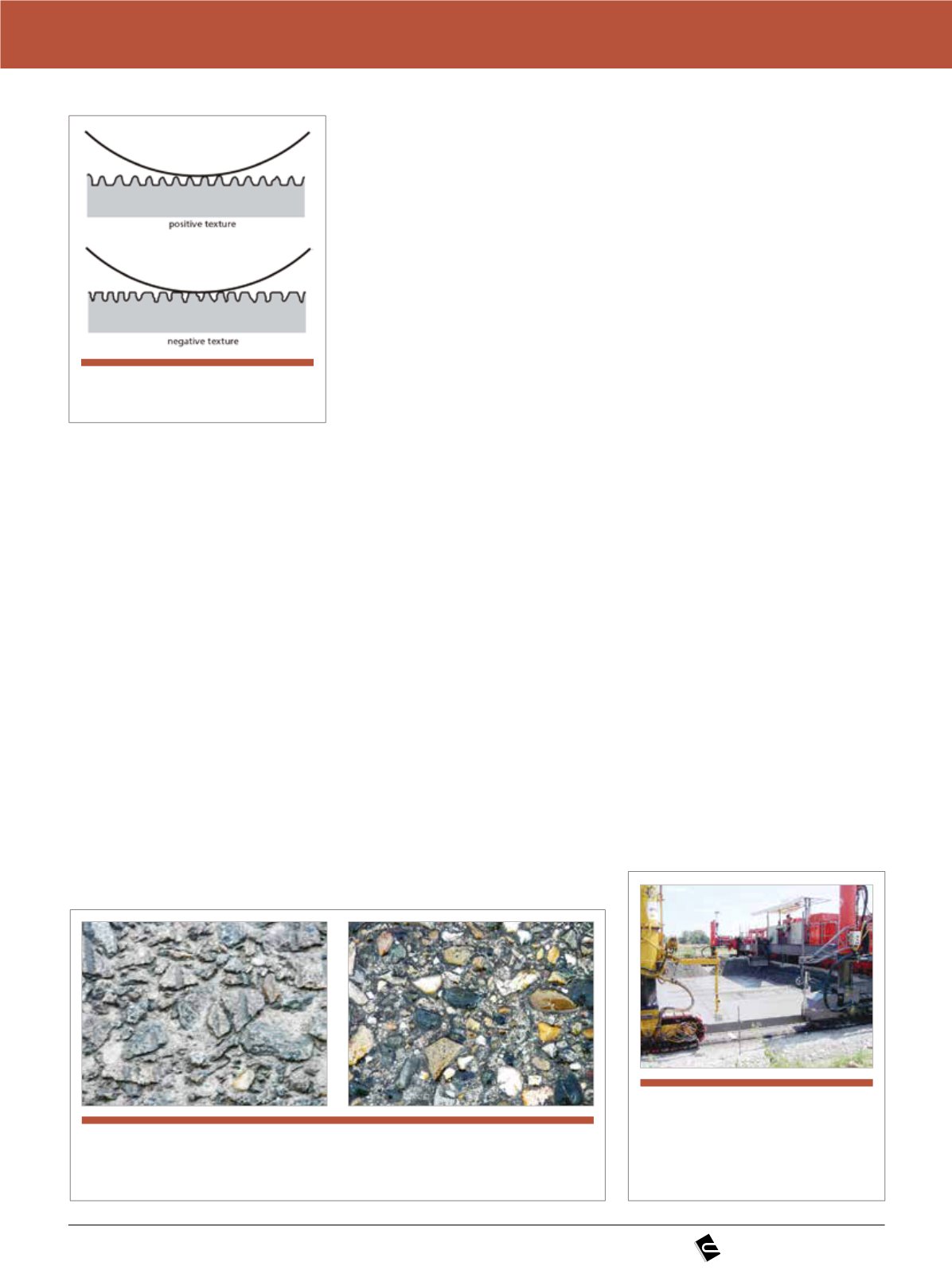

u

Figure 5

Coarse concrete 0/40 or 0/32, left, based on porphyry aggregates,

and right, based on crushed gravel

u

Figure 6

Two slipform pavers laying a

double-layered jointed plain

concrete pavement on the A1,

near Vienna