60 | CONCRETO & Construções

u

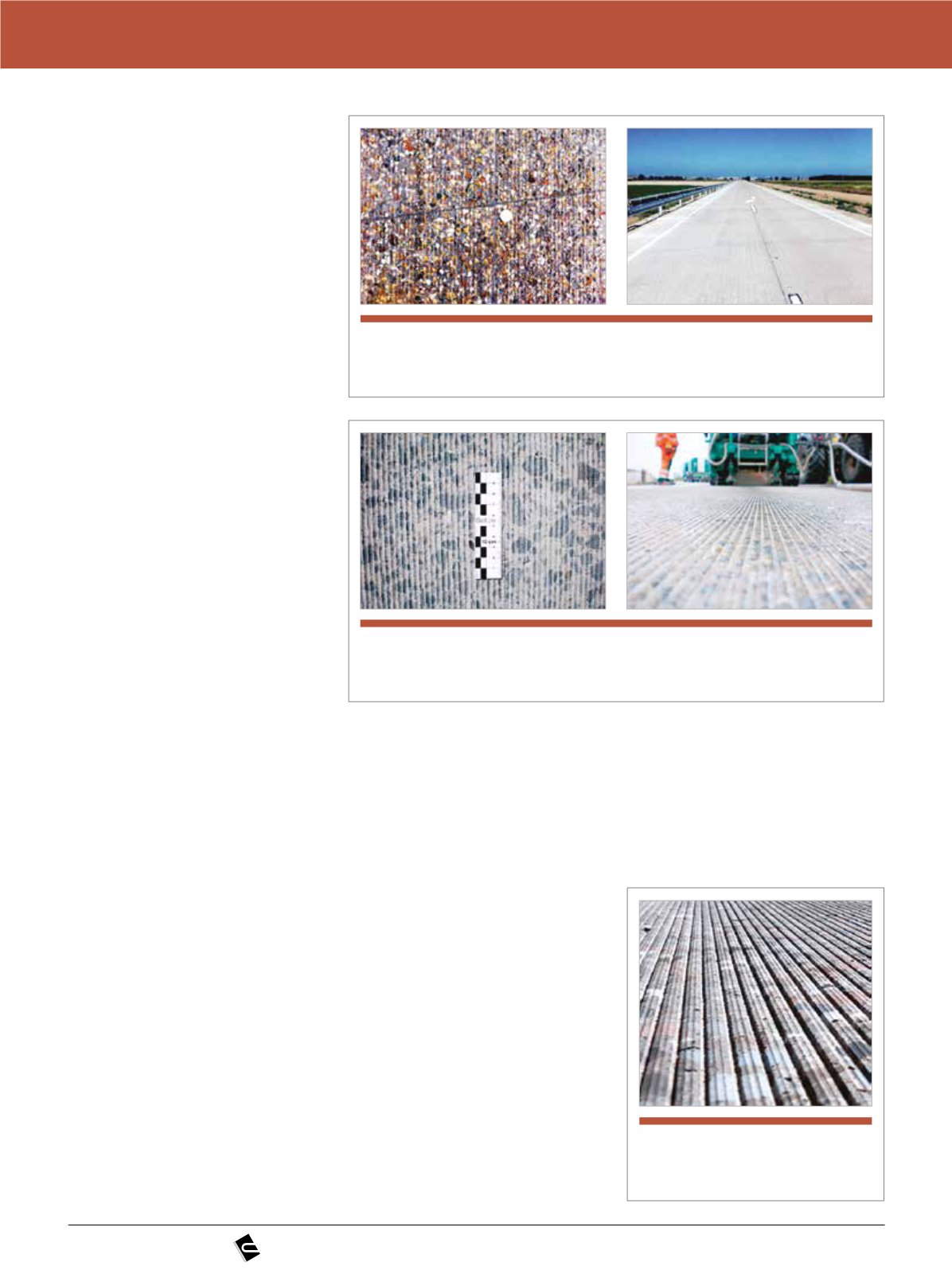

Figure 12

Detail of the micro-milled surface and view of the motorway in Leon,

Spain (IECA)

5. OTHER LOW-NOISE SURFACE

FINISHING TECHNIQUES

5.1 Longitudinal tining

In the U.S.A., other finishing tech-

niques are used as well. In many states,

fine longitudinal grooves are applied to

the fresh concrete with a comb. This

also produces good results in terms of

noise and skid resistance, as long as

the process is carefully applied. This

technique is not being used in Europe.

5.2 Micro-milling

Micro-milling (or fine milling) is

a surface restoration technique us-

ing conventional cold mills of which

the cutting teeth are more closely

spaced on the milling drum.

Although it is mostly used on sec-

ondary roads, micro-milling can be

an alternative on motorways as well.

This was the case in Leon (Spain).

Acoustic characteristics have not

been measured but based on earlier

trial sections in Belgium, the rolling

noise level is about 1dB higher com-

pared to a diamond ground surface.

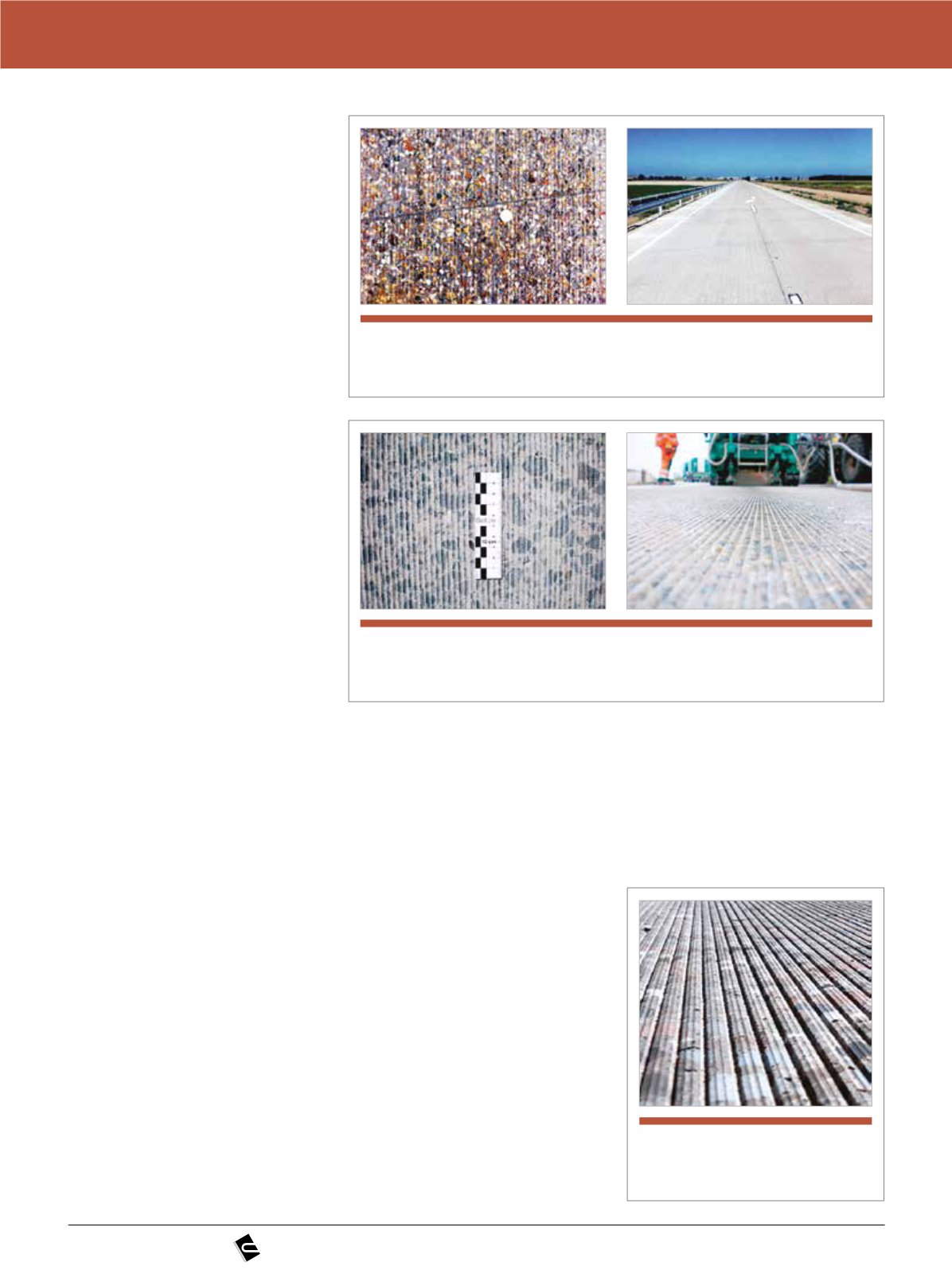

5.3 Diamond grinding

The technique of longitudinal tin-

ing of the hardened concrete, known

as “diamond grinding” is also often

used. This technique has already

been used frequently in several

countries for the restoration of ex-

isting concrete surfaces. This can

result in tyre-pavement noise levels

that are even lower than for exposed

aggregate concrete.

In 2009 a trial section in CRCP was

built in Germany, the “Geseke access

road” pilot project, in order to inves-

tigate the different surface character-

istics of the diamond ground texture

(Ref. 12). The surface was finished

with a longitudinally aligned ground

texture whereby two different groove

spacing distances (blade spacing 2

mm and 3 mm / blade width 3,2 mm /

grinding depth 3mm) were implement-

ed. Measurements with the CPX-trail-

er revealed excellent results : as low

as 94,9 dB(A) for the 2mm texture.

Repeated measurements in 2013

showed virtually unchanged noise lev-

els (95,2 dB(A)), confirming the high

durability of the ground texture.

5.4 Next Generation Concrete

Surface (NGCS)

In the U.S., the International

Grooving and Grinding Association

(IGGA) has developed a smoother

and even quieter surface, socalled

“Next Generation Concrete Surface”

(NGCS). A thin layer of concrete

surface is removed through the

u

Figure 13

Detail view of the diamond ground surface and texture of the “Geseke

access road” in Germany (S. Riffel (2014))

u

Figure 14

“NGCS” (International Grooving

and Grinding Association)