58 | CONCRETO & Construções

prone to ravelling (aggregates com-

ing loose from the surface).

4. LOW-NOISE EXPOSED

AGGREGATE CONCRETE

The technique of aggregate ex-

posure is today the most frequently

used surface finishing method on

concrete motorways in Europe. It

offers a comfortable surface com-

bining a good skid resistance with a

low rolling noise.

In the late 1970s, in Belgium,

surface finishing by chemically ex-

posed aggregate concrete was in-

troduced. The aim was above all to

achieve skid resistance, but tyre-

pavement interaction noise was not

yet a criterion. The concrete compo-

sition consisted of large aggregates

(32 to 40 mm) which were exposed

on the surface. These were highly

noisy pavements and are no longer

applied today.

In Austria, the fine exposed ag-

gregate concrete was optimised as

the surface layer of a double-layer

jointed concrete pavement. The bot-

tom layer (15 to 20 cm thick) may

contain larger stones up to 31.5 mm,

while for the top layer, (5cm thick)

only durable polish-resistant stones

with a maximum aggregate size of 6

to 11 mm are used. Since the top

layer mixture consists exclusively of

small aggregates, these will emerge

densely distributed on the surface

after compaction of the concrete

and washing out of the surface.

The first applications on Austrian

highways date back to 1990. Since

then, a significant part of the high-

way network has been constructed

in this way.

In Germany, for many years, the

concrete road surfaces were finished

with a dragged burlap cloth. This

produces a very shallow texture that

is effective in terms of tyre-pavement

noise but can lead to problems con-

cerning skid resistance. That is why,

for the past few years, the technique

of double-layer exposed-aggregate

concrete has been applied.

In Belgium, a first step in improv-

ing the exposed aggregate concrete

was the reduction of the maximum

aggregate size from 31.5 to 20 mm.

Moreover, the proportion of fine

aggregate, measuring from 4 to

6.3mm (or 8mm), was increased to

a minimum of 20% (or 25%) of the

mixture of sand and gravel. In this

way, the larger stones sink and the

smaller ones rise during the vibration

of the concrete. After exposing the

aggregates by brushing, the smaller

aggregate will lie on the surface and

form the proper macro texture for a

quiet concrete pavement. The same

technique can also be applied for a

maximum aggregate size of 14 mm.

By further optimising the com-

position (high content of fine ag-

gregate) and a better application

technique (modern slipform pavers),

it has been possible to further re-

duce the tyre-pavement noise of a

u

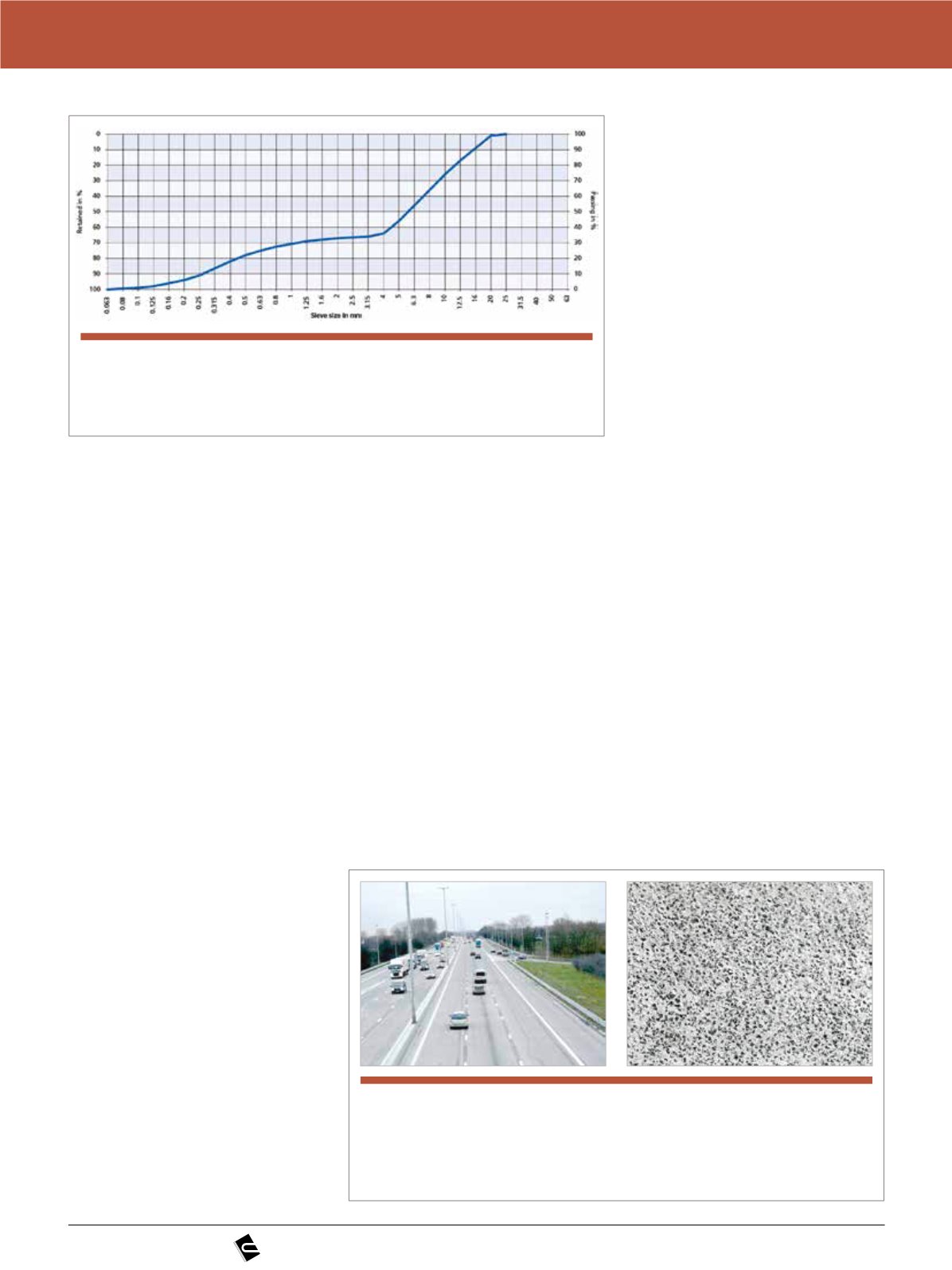

Figure 7

Grading curve of a concrete mix with a Dmax of 20 mm and a higher dose

of small aggregates (4 to 8mm) for a low-noise single layered

exposed-aggregate concrete pavement

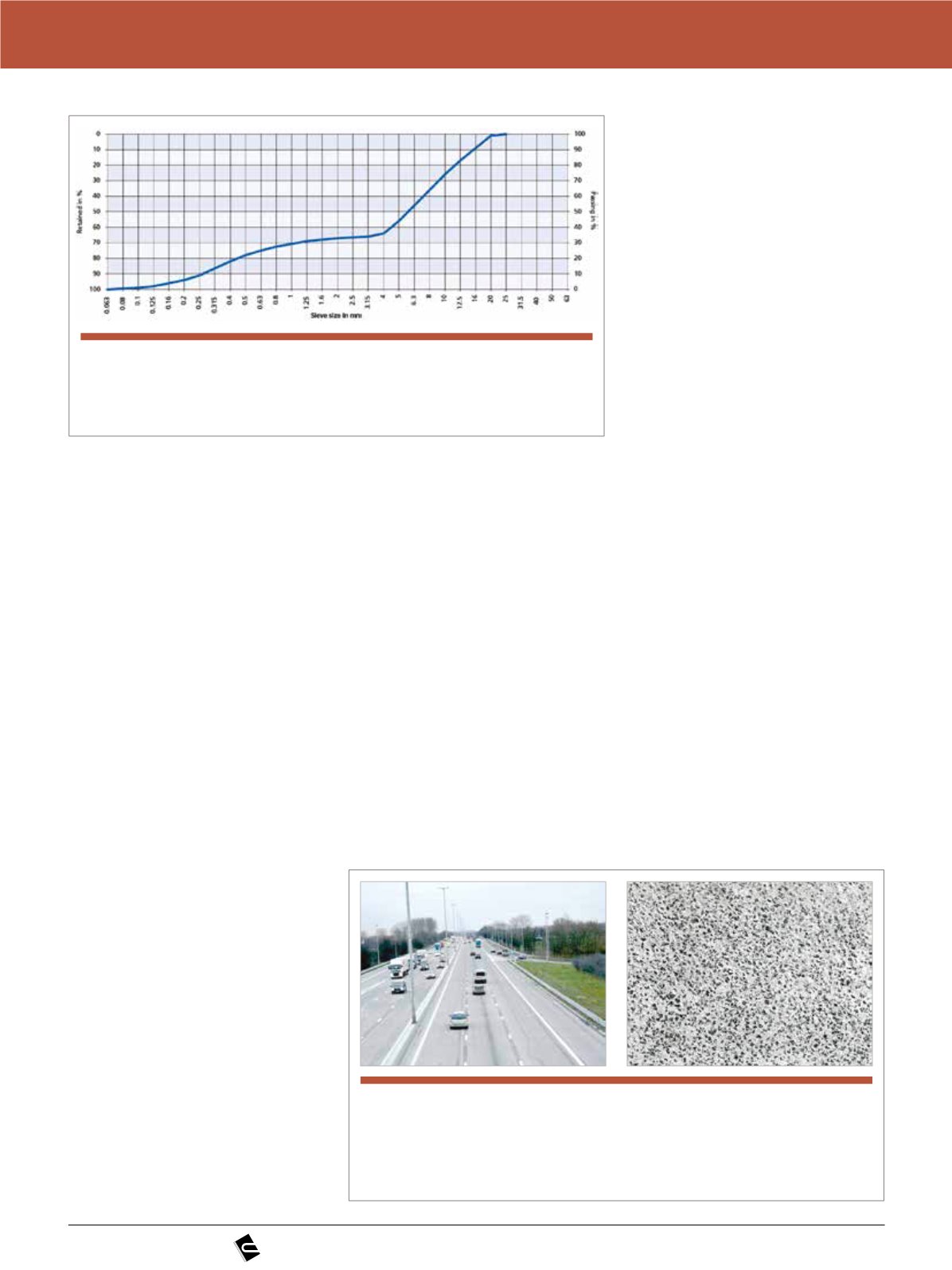

u

Figure 8

E17 De Pinte – Kruishoutem: single-layer exposed-aggregate

concrete 0/20

Noise levels measured with CPX at 80 km/h: 98.5 dB(A) for a truck

tyre and 99.1 dB(A) for a passenger car tyre