66 | CONCRETO & Construções

surface was sealed in construction),

the permeability of the subgrade usu-

ally has the largest impact on the

drainage rate of the system. For the

engineer or the regulator, it is impor-

tant to know the drainage rate of the

pervious concrete system to know

that it is functioning as designed. For

the concrete contractor, it is important

to know the infiltration rate of storm-

water at the pavement surface, imme-

diately after curing, to know that the

pavement was installed correctly.

When considering just the con-

crete layer in the system, the rate of

surface infiltration will be impacted

by the gradation of the coarse aggre-

gate, the maximum aggregate size,

the design density of the pavement,

the relative density achieved during

construction, the vertical porosity dis-

tribution [Haselbach 2006], and the

amount of clogging by foreign materi-

al. Of these, the first three factors are

impacted by raw material selection by

the concrete producer. Whereas, we

have C 1747 to test the raveling po-

tential of a pervious concrete mixture

prior to construction, we don’t have

an equivalent, standardized, labora-

tory test to quantify the drainage po-

tential at the same point in the project.

ASTM C 1701 was designed to

measure the drainage rate (permea-

bility) of the concrete layer. However,

even this has limitations. If the system

is saturated, stormwater can back up

into the pervious concrete layer. When

testing, this mound of stormwater can

produce artificially low drainage rates

through the pavement. This is why C

1701 includes the text, “Do not repeat

this test more than twice at the same

location on a given day.”

When this test was developed, the

ASTM group thought it was best to be

used only to measure reductions in

surface infiltration to help owners de-

cide on proper maintenance. As the

industry has evolved, contractors have

begun to use it to protect their inter-

ests and prove the pavement surface

drained well immediately after cur-

ing. This would protect them from a

claim if the pavement were to become

clogged either by other trades, during

construction, or by outside influences

after construction. The ASTM sub-

committee expects to change the sig-

nificance and use of this test to allow it

to be used to prove that the contractor

installed the material properly.

5. STRUCTURAL ISSUES

Vertical and horizontal applications

need to be considered separately

when considering structural issues

with pervious concrete. While the

history and oldest applications of the

material were in structural walls, the

body of work today is primarily in non-

structural applications.

The biggest difference in perfor-

mance between pervious concrete

and plain concrete comes from con-

solidation. Both types of concrete

require densification to develop their

maximum strength. However, in nor-

mal concrete, aggregates are well

graded and there is paste between

the aggregates, which allows the

concrete to flow when vibratory en-

ergy is applied in the form of rodding

or mechanical vibration. This flowing

property is what allows plain concrete

to be consolidated to a consistent,

repeatable density. With pervious

concrete, however, there are no fine

aggregates and only a thin coating of

paste exists between the coarse ag-

gregate particles, so this flow does

not occur when the concrete is vibrat-

ed. The only way to get repeatable

and predictable density is to apply a

repeatable amount of compactive en-

ergy [Offenberg 2008].

For vertical applications, typically

walls, pervious concrete is not used

in the US, today. In the future, pervi-

ous concrete may return to vertical

u

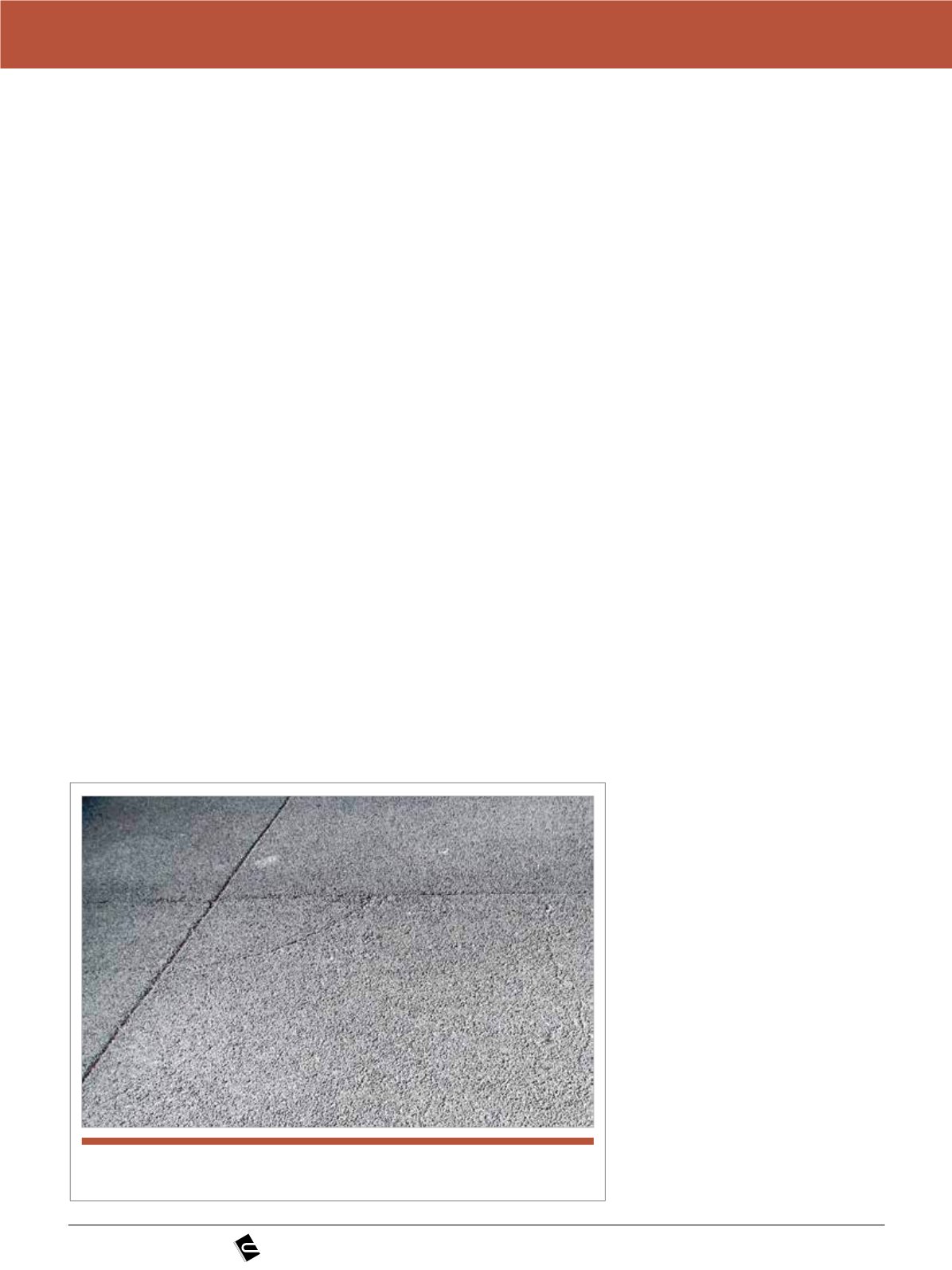

Figure 3

Structural cracking in a pervious concrete pavement without raveling