CONCRETO & Construções | 63

and the permeability decreases [FCPA

1990 – Pervious Pavement Manual].

While there are a number of means and

methods for achieving compaction, the

art of the contractor is to use his specif-

ic equipment to work with the concrete

to achieve an optimal density.

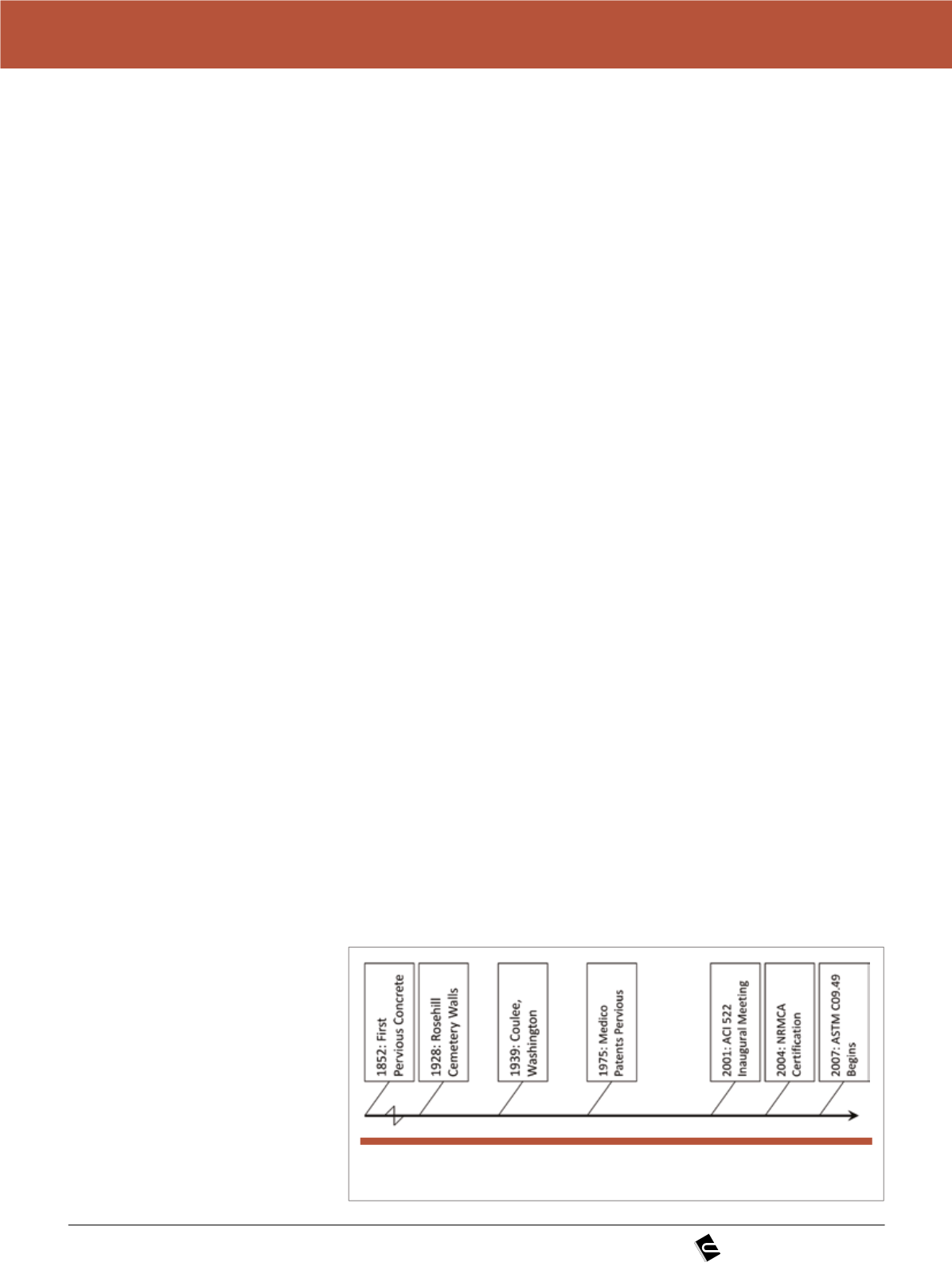

1.2 Growth of pervious concrete

In the US, pervious concrete has

seen significant growth since 2001,

both in the marketplace and in the re-

search community. Historically, there

are a few key milestones that have each

contributed to the interest in this tech-

nology. The introduction of the ACI,

NRMCA, and ASTM committees each

had a significant impact on the adop-

tion of pervious concrete.

First, in 2001, the American Con-

crete Institute (ACI) launched commit-

tee 522 on pervious concrete. This

group was tasked with collecting and

documenting the world’s knowledge

on the topic, and eventually develop-

ing guide specifications for pavement

applications [ACI 2013]. The industry

celebrated the release of the first guide

for pervious concrete in 2006, but more

important, this group brought together

all of the minds working on pervious

concrete in North America. So, the

contractors and concrete producers

could network with the engineers and

researchers. This brought about an ex-

plosion of research and knowledge on

the topic.

Then, in 2004, the National Ready

Mix Concrete Association (NRMCA)

launched a program to begin certify-

ing individual contractors in the art of

pervious concrete. The certification

program used the knowledge gathered

by the ACI committee to develop a

book to teach contractors about plac-

ing pervious concrete [NRMCA 2007

- Text Reference for Pervious Concrete

Contractor Certification, Publication

2ppcrt], and developed presentations

and hands-on demonstrations to ac-

company a classroom session. With

three levels of certification, the program

accommodates contractors of all ex-

perience levels to prepare or enhance

their skills for the jobsite. As of this writ-

ing, over 10,000 individuals have been

trained through this program, globally.

In 2007, ASTM created a subcom-

mittee under its Concrete and Ag-

gregates committee, designated as

C09.49. This group was to standardize

test procedures for pervious concrete.

Task groups were formed to work

on testing: fresh density, hardened

density, surface permeability, flexural

strength, compressive strength, and

raveling resistance. Since its inception,

C09.49 has released four standard test

methods, and updated versions total-

ing nine documents.

With ACI giving information to speci-

fiers so they could design pervious con-

crete pavements correctly; the NRMCA

certifying contractors to help them build

high-quality pervious concrete pave-

ments; and ASTM showing the world

how to ensure the pervious pavement

was built to specification, the industry

was well positioned for growth.

2. STANDARDIZED TEST

METHODS FOR PERVIOUS

CONCRETE

With ASTM subcommittee C09.49

developing standardized test methods

for pervious concrete, the goal was

to ensure that stormwater and zoning

regulators, property owners and specifi-

ers had a way to verify that constructed

pavements would perform as designed.

Research shows that one key indica-

tor of quality is concrete density [FCPA

1990, Offenberg 2011]. The first pri-

ority, then, was to document tests for

fresh and hardened density.

The earliest specifications for pervi-

ous concrete included testing the fresh

density as an indicator of concrete qual-

ity. If the concrete was batched and

mixed consistently load-to-load, then

the density of the fresh concrete should

be similar. These early documents re-

quired jigging the concrete as a means

of consolidation.

ASTM’s C09.49 task group, led by

Michael Davy, evaluated six different

methods for compaction of a fresh con-

crete sample in a cylindrical container

with a capacity of 7.0 +/- 0.6 L [0.25

+/- 0.02 ft

3

]. These included: No com-

paction, rodding as described by ASTM

C 138, jigging as described by ASTM

C 29, 20 drops of the Proctor Hammer,

and five and ten drops of the Marshall

u

Figure 1

Timeline of pervious concrete history in the United States