Basic HTML Version

157

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 2

P. B. ARISTIMUNHO | S. R. BERTOCINI

ence, and the 10% replacement of cement was less impaired and

reached 17 MPa at 90 days.

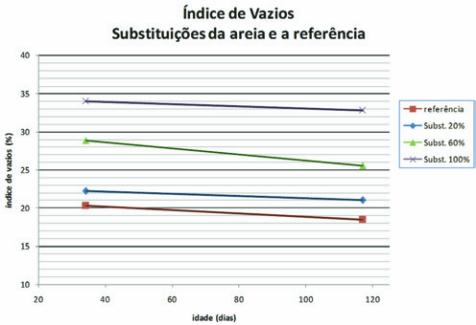

3.4 Void ratio

Void ratio (ratio between pore volume and the volume of solids) is

directly proportional to the porosity of the material. Void ratio test

was carried out only for the group of sand replacements and the

reference, as shown in Figure 6.

It is observed that void ratio increases as the percentage of sand

replaced by iron ore in powder increases. A larger amount of fine

material affect the workability of the mortar and the compression of

the layers. The mixtures were prepared applying the same energy

of compression. An interesting suggestion is to apply higher en-

ergy of compression or use superplasticizer in sand replacements

mixtures in order to reduce the void ratio. In general, when the void

ratio decreases and, consequently, the porosity, the compressive

strength is increased (Neville [10]).

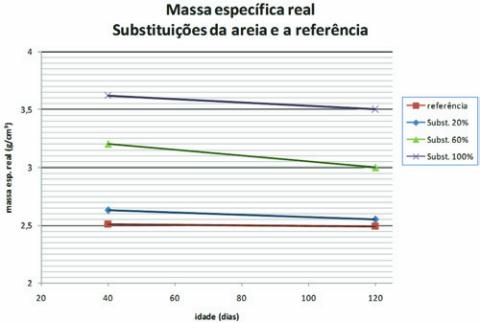

3.5 Specific mass

The specific mass results were showed and discussed only for

specimens with sand replacements, because this group presented

the most significant values, while the others groups practically

Figure 6 – Chart of void ratio of

sand replacements and reference

Figure 7 – Chart of specific mass

of sand replacements and reference

Figure 8 – Visual comparison of red color,

reference and sand replacements

Table 3 – Compression strenght, w/c ratio and consistency index of cement replacement and reference

Compositions

Mixture in mass

cement: sand: IO

powder

water/cement

ratio

Results of compression strenght

in MPa

Flow

Table

(mm)

7 days

28 days

90 days

OBS: IO=iron ore

Reference

1 : 3 : 0

0,60

16,14

24,55

24,36

243

Cement Replacement 10%

1 : 3,3 : 0,1

0,60

11,56

15,66

17,15

243

Cement Replacement 20%

1 : 3,75 : 0,25

0,60

10,1

8,75

16,51

242

Cement Replacement 30%

1 : 4,3 : 0,43

0,60

9,46

8,79

11,16

241