Basic HTML Version

156

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 2

Application of iron ore mud in powder form in portland cement presence

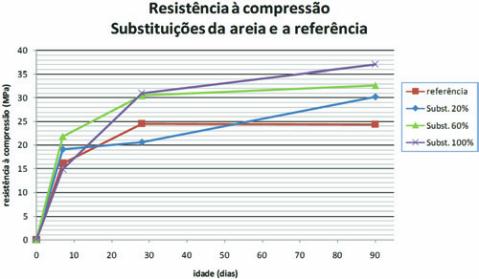

3.2 Sand replacement

Table 2 presents the mean results of the compressive strength at

ages 7, 28 and 90 days of the sand replacements of 20%, 60%

and 100% and reference, as well as their consistency indexes and

water/cement ratio.

With the increased amount of powder, the workability of the mortar

is damaged, requiring addition of mixing water. In the case of mor-

tars with sand replacement was necessary to increase the water/

cement ratio in order to maintain an adequate workability. The low-

est consistency index was observed in the sand replacement of

100%, even with the highest water/cement ratio.

According to Figure 4, virtually all resistances are higher than the

reference, especially the replacement of 100% reaching 37 MPa

at 90 days.

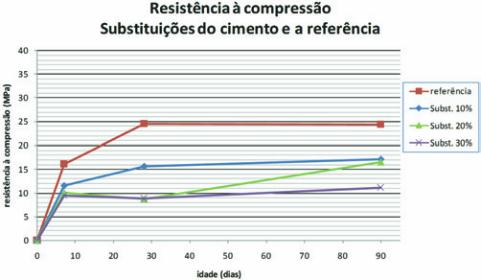

3.3 Cement replacement

Table 3 presents the average results of the compressive strength

at ages 7, 28 and 90 days of cement replacements of 10%, 20%

and 30% and the reference, as well as their consistency indexes

and water/cement ratio. It is observed that the consistency index

and the water/cement ratio did not change significantly.

According to Figure 5, all resistances are lower than the refer-

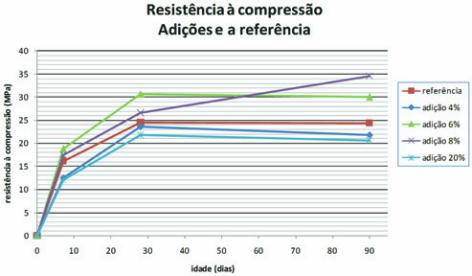

According to Figure 3, the additions of 4% and 20% present lower

resistances than the reference, while the additions of 6% and 8%

have a higher resistance. Note that the resistance of addition of 6%

tends to fall from the 50th day, but the resistance of addition of 8%

tends to rise over time and reaches 35 MPa at 90 days.

Figure 3 – Chart of compression

strength of additions and reference

Table 2 – Compression strenght, w/c ratio and consistency index of sand replacements and reference

Compositions

Mixture in mass

cement: sand: IO

powder

water/cement

ratio

Results of compression strenght

in MPa

Flow

Table

(mm)

7 days

28 days

90 days

OBS: IO=iron ore

Reference

1 : 3 : 0

0,60

16,14

24,55

24,36

243

Sand Replacement 20%

1 : 2,4 : 0,6

0,60

19,14

20,59

30,23

242

Sand Replacement 60%

1 : 1,2 : 1,8

0,65

21,84

30,48

32,65

243

Sand Replacement 100% 1 : 0 : 3

0,76

14,82

30,98

36,98 213

Figure 4 – Chart of compression strength

of sand replacements and reference

Figure 5 – Chart of compressions strength

of cement replacements and reference