Basic HTML Version

6

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 1

Steel fiber reinforced concrete pipes. Part 1: technological analysis of the mechanical behavior

hardening pattern, which consists of increasing resisted load with

increasing vertical displacement of the pipe. Thus, the resistance

displayed by pipes with regular reinforcement was largest than the

presented by FRCP at higher displacements. However, for lower

strain, the residual strength capacity was greater for FRCP. This

occurs because the bars are positioned at the innermost part of

the pipe wall and they are mobilized more intensely when there

is greater displacement and hence higher level of cracking. On

the other hand, the fibers are distributed throughout the thickness

of the pipe wall. Thus, the fibers reinforcement is mobilized with

small levels of displacement and cracking, which provides better

performance in this situation.

In order to facilitate the analysis of the influence of the setups for

measuring displacements in the pipes during the crushing test

the results of the average curves obtained with the greater fiber

content are presented in Figure [17]. The results obtained in the

1

st

Series, where the displacement measurements were made at

the spigot and at the socket simultaneously, had presented higher

stiffness in the beginning of the curve. The end of the initial elastic

line was prolonged by the influence of the socket region where the

concrete matrix contributes more intensely [14]. For the 2

nd

Series,

where the displacements were measured only at the spigot, they

were more intense for smaller loads, due to lower rigidity of this part

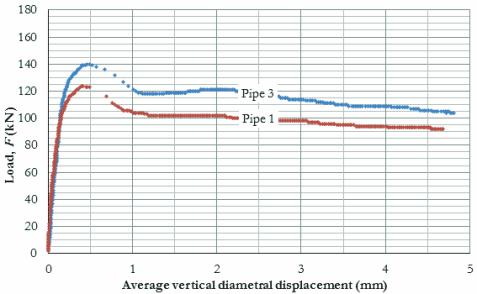

Figure 8 – Load versus displacement curves

obtained during crushing test of pipes with a

3

fiber consumption of 20 kg/m and with the

diametrical displacement measured

at the spigot and the socket

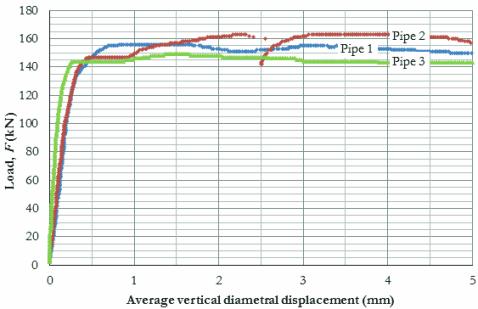

Figure 9 – Load versus displacement curves

obtained during crushing test of pipes with a

3

fiber consumption of 40 kg/m and with the

diametrical displacement measured

at the spigot and the socket

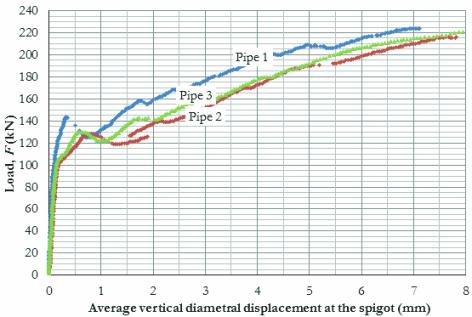

Figure 10 – Load versus displacement curves

obtained during crushing test of pipes with a

conventional reinforcement and with the

diametrical displacement measured

at the spigot and the socket

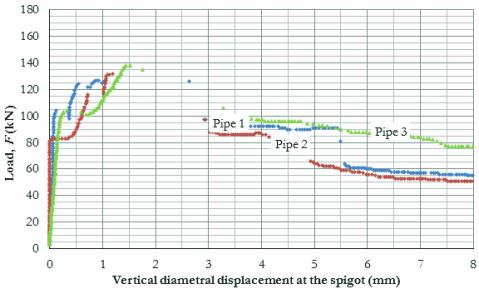

Figure 11 – Load versus displacement curves

obtained during crushing test of pipes with a

3

fiber consumption of 10 kg/m and with the

diametrical displacement measured

only at the spigot