Basic HTML Version

5

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 1

A. D. de Figueiredo | A. de la Fuente | A. Aguado | C. Molins | P. J. Chama Neto

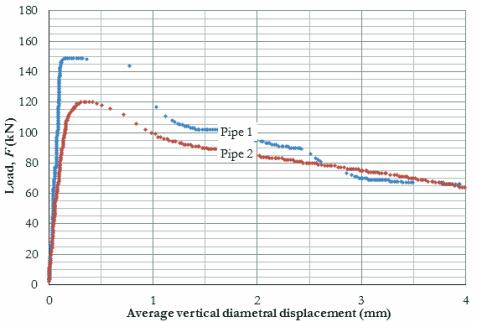

due to failures in the test system, where the reading of the strain

was impaired. Because of that, only two curves are shown in Fig-

ures [7] and [8].

The fact that pipes have been tested in real scale caused a re-

duction of the results variability. In ordinary tests to determine the

toughness of fiber reinforced concretes, the coefficient of variation

can exceed 20% [12]. This occurs because the crack area (where

the fibers act as a stress transfer bridge) is much larger in a tube

than in a prismatic specimen. This reduction in variability has been

observed in previous studies [7 and 13].

The first perceptible aspect was the behavior with a well defined

pattern for pipes reinforced with smaller amounts of fiber. This

softening pattern was characterized by a reduction of the strength

of the pipe with increasing vertical displacement. The pipes re-

inforced with steel bars or 40 kg/m

3

of fibers had presented a

Table 2 – Differences between the two series of pipes used in the experimental study

Series

LVDT position

Cement

Water content

First

At the spigot and socket

Brand 1

3

Fixed on 141 liters/m

Second

Only at the spigot

Brand 2

Adjusted for each mix (constant consistency)

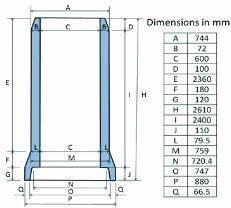

Figure 5 – General appearance of a

new fiber reinforced concrete pipe

Figure 6 – Geometric characterization

of the pipe used in the experiment

Figure 7 – Load versus displacement curves

obtained during crushing test of pipes with a

3

fiber consumption of 10 kg/m and with the

diametrical displacement measured

at the spigot and the socket