Basic HTML Version

170

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 2

Study of the reuse of construction residues in concrete employed by blocks manufacture

found by researchers Boldrin et al. [1]; Lintz and Simonetta [21] for

these physical characteristics.

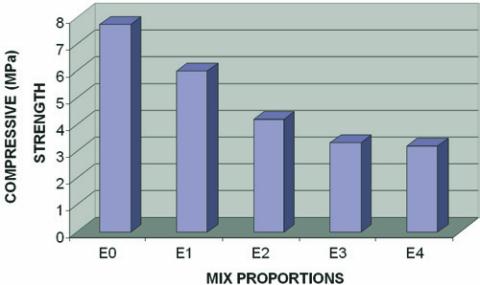

As for the compressive strength of the concrete specimens, com-

positions E1, E2 accounted for 94% and 58% of the value given for

the reference mixture (E0). For the other mixtures the fall for this

property was substantial.

For the tensile strength by diametrical compression, compositions

E0, E1 and E2 have values within the limits of resistance of con-

crete blocks.

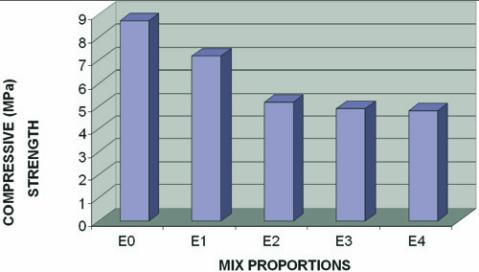

As for the compressive strength of concrete blocks, the

NBR6136:2007 [22] classifies simple concrete blocks masonry,

into four classes, as shown in Table 2, being classified for use in:

Class A - With structural function, for use in masonry elements

above or below ground level;

Class B - With structural function, for use in masonry elements

above ground level;

Class C - With structural function ,for use in masonry elements

above ground level;

Class D - No structural function, for use in masonry elements

above ground level;

It can be observed that for all concrete mixes used in the manufac-

ture of the blocks the compressive strength values are within the

limitations of the Brazilian standard for use as part of the masonry.

The blocks executedwith themix concrete reference E0 and themix con-

crete E1, showed resistance above 6 MPa at 28 days, being classified

as “Class A” and the others meet the strength characteristics of “class B”.

Figure 7 – Results of average compressive

strength of concrete blocks at 14 days

Figure 8 – Results of average compressive

strength of concrete blocks at 28 days

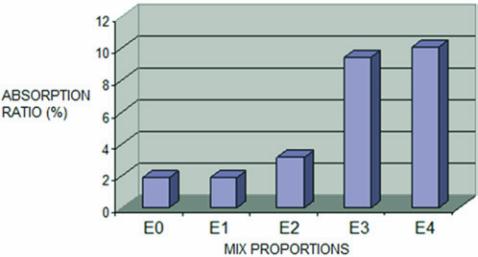

Figure 9 – Test results of water absorption

by immersion of specimens

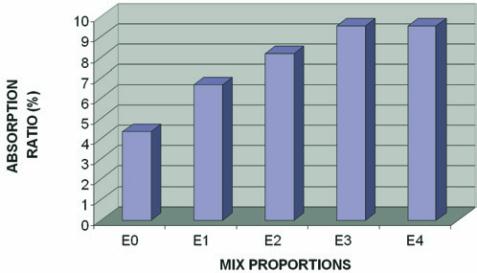

Figure 10 – Test results of water absorption

of concrete blocks

Table 2 – Requirements for characteristic

compression strength of

concrete blocks (NBR6136)

Class

Strength Feature (f ) MPa

bk

A

≥

6,0

B

≥

4,0

C

≥

3,0

D

≥

2,0