Basic HTML Version

169

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 2

R. C. C. Lintz | A. E. P. G. A. Jacintho | L. L. Pimentel | L. A. Gachet-Barbosa

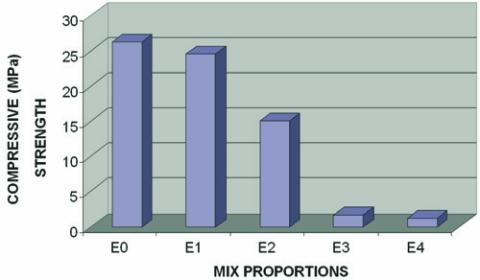

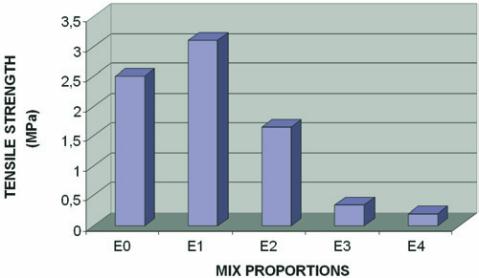

sive strength and tensile strength by diametrical compression for

the cylindrical specimens, at 28 days. Figures 7 and 8 show the

results from the compression tests of concrete blocks, at 14 and

28 days. Figures 9 and 10 show the rates of water absorption by

immersion for the cylindrical specimens and values of water ab-

sorption capacity of concrete blocks, respectively. Both absorption

tests were performed at 28 days of curing.

Through the analysis of data from the characterization tests, it was

observed that the natural aggregates have higher specific and sin-

gle densities than the recycled aggregates, confirming the results

The mixture was made in intermittent concrete mixer of inclined

axis (NBR5738:2008 [20]), and later the specimens were moulded

on the vibrating table and cured, submerged in a tank of saturat-

ed water with lime, for 28 days, according to the specifications of

NBR5738:2008 [20]. After curing, the cylindrical specimens were

rectified for execution of the tests and the blocks capped.

3. Results and discussion

Figures 5 and 6 show the results obtained from tests for compres-

Table 1 – Physical characterization of aggregates

Material

Specific

mass (Kg/l)

Unitary

Mass (Kg/l)

Maximum dimension

Feature (mm)

Fineness

Modulus

Granulometric

Qualification

Natural

Fine

aggregate

2,62

1,47

2,4

1,93

zone 2

fine sand

Natural

Fine

aggregate

2,90

1,63

4,8

2,74

zone 3

medium sand

Natural

Coarse

aggregate

2,86

1,64

9,5

6,67

gravel 0

Natural

Fine

aggregate

2,34

1,33

4,8

2,38

zone 3

recycled

medium sand

Natural

Coarse

Aggregate

2,55

1,46

9,5

3,36

recycled 0

gravel

Figure 5 – Results of average compressive

strength of cylindrical specimens

Figure 6 – Results of tensile strength by average

diametrical compressive of cylindrical specimens