Basic HTML Version

256

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 2

Three-dimensional analysis of two-pile caps

(3)

,inf

min ,

ctk

y f

ct

f h h

R

× ×

=

(4)

2

2

)

4 2

(

d a L

h

x

est

f

+ +

=

Where:

R

ct, min

: minimum tensile force;

h

f

: vertical dimension – strut and tie model (Delalibera [1]);

h

y

: column cross-section;

f

ctk, inf

: inferior value of concrete characteristic tensile resistance;

L

est

: piles span;

A

x

: pile dimension in the considered direction.

2.4 Analysis method

The Newton-Rhapson analysis method was adopted with a con-

centrated load at the center of the column’s superior cross-section

and force increments of 25 kN. Added to this, an hexahedral finite

elements mesh was adopted to pile caps, piles and columns as

shown in Figure 5. And a tetrahedral finite elements mesh was

adopted for the steel plates.

Absolute (100%) and partial (50% and 25%) vertical movement

restraints were imposed to piles base supports. At piles-pile cap

and column-pile cap contact surfaces a finite elements 3D inter-

face was used based on Mohr-Coulomb criterion. Their properties

are presented in Table 6.

3. Considerations on numerical

and experimental models

3.1 Divergences between numerical

and experimental models

One of the most discrepant structural behaviors observed between

numerical and experimental models was in the stiffness pile caps,

which was much higher in numerical models. This fact demon-

strates the inherent complexity of laboratory experiments.

Delalibera [1] points out three main reasons for this stiffness differ-

ence, which are prototype accommodation at the beginning of the

experiment, perfect bond assumption between steel bars and con-

crete in numerical models and perfect connection between piles

and pile cap.

In reference to the first reason, [1] cites pile cap accommodation at

the beginning of the experiment, which was verified in load versus

displacement curve. About the second reason, the author did not

confirm this hypothesis after the preliminary tests. And in respect

to the third reason, [1] affirms that this is probably what has mainly

collaborated to the augment in pile cap’s stiffness, since a detach-

ment between piles-pile cap interface occurred. Therefore, [1] sug-

gests the use of interface finite elements on the contact surfaces of

the structural elements.

Following the recommendation of [1], all numerical pile caps were

modeled using a finite elements interface between column-pile cap

contact and piles-pile cap contacts. Moreover, the supporting area

of the piles was reduced in order to observe pile caps stiffness

behavior.

The reduction of the supporting area of the piles enabled an in-

crease in pile caps strains and displacements. This fact is in accor-

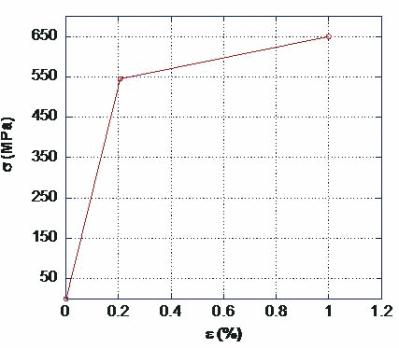

Table 4 – Reinforcement properties

Poisson’s ratio (

n

)

0,3

Modulus of Elasticity (E )

s

210 GPa

Yield Strength (f )

yk

545 MPa

Ultimate Tensile Strength (f )

tk

650 MPa

Yield Strain (

e

)

yd

0,207%

Ultimate Strain (

e

)

lim

1%

Table 5 – Steel plates properties

Poisson’s ratio (

n

)

0,3

Modulus of Elasticity (E )

s

210 GPa