Basic HTML Version

88

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 1

Reliability of buildings in service limit state for maximum horizontal displacements

and beams are multiplied by 0,70. In the second model, equivalent

stiffness are obtained by multiplying the stiffness of columns and

beams by 0,80 and 0,40, respectively. In this article, these models

are referred to as 70/70 and 80/40, respectively.

The secant Young´s modulus of concrete is:

(7)

sec

0.85 5600

E

fck

= ×

where:

E

sec

: secant Young´s modulus;

f

ck

: characteristic concrete resistance at 28 days.

3. Model errors

The simplified stiffness reducing models proposed in ABNT

NBR6118:2003 [1] are, naturally, approximations of reality. A

variable that measures the accuracy or precision of these, called

model error, is obtained by dividing the displacements obtained

via a rigorous material non-linear analysis by the displacements

obtained using the simplified model (OLIVEIRA et al. [9]):

(8)

rigorous

simplifyed

M

u

E

u

=

This is a random variable as, for different structures, the simplified

model can be more or less precise. One sample (set of observa-

tions) of the model error random variable is obtained by evaluating

equation (8) for a set of different structural configurations. In this arti-

cle, a sample of the two model error random variables is obtained by

evaluating 42 representative plane frames of different geometries,

materials and reinforcement ratios. Frames of four, eight and twelve

floors are considered, with one to three bays. The studied frames

are variations from the frames represented in Figure 3. Concrete

resistances varied from 20 to 40 MPa. Three reinforcement ratios

were considered: low, medium and high. The low reinforcement ratio

is close to the lower limit, medium is around 2% and high is close to

the upper limit (3 to 4%) allowed in ABNT NBR6118:2003 [1]. Verti-

cal loading was determined based on the process of influence areas

(slabs, beams, columns, walls and coverings). Accidental load was

adopted as 1,5 kN/m² in the influence area. Details of the studied

frames are presented in Table 1. The table also presents the model

error observations obtained for these frames.

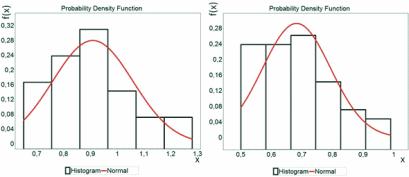

Figure 4 shows the histograms that were obtained from the model

error samples, as well as the probability distribution functions that

were adjusted to the data. For the simplified model with 70/70 stiff-

ness reduction, a Normal distribution was obtained with parameters:

(9)

E

M

70/70

~N(μ=0.908, σ=0.150)

For the simplified model with 80/40 column/beam stiffness reduc-

tion, a Normal distribution was obtained with parameters:

(10)

E

M

80/40

~N(μ=0.682, σ=0.111)

The coefficient of variation (c.o.v) is similar for both models error

variables (σ/μ=0.16).

The Normal distribution resulted in a good fit for both variables, as

indicated by the statistics shown in

Table 2

. For both cases, the

Normal distribution passed the Kolmogorov-Smirnov, Anderson

Darling and Chi-square goodness-of-fit tests.

Figure 4 – Histograms and probability distribution functions of model error variables:

70/70 stiffness reduction (left), 80/40 column/beam stiffness reduction (right)