Basic HTML Version

72

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 1

The influence of low temperature on the evolution of concrete strength

4. Presentation and Result Analysis

After the rupture of the specimens in the mechanical tests, it was

compared the results to reach conclusions regarding the subject.

4.1 Trial of compression of the cylindrical specimens

The results of the resistance to compression were divided into two

stages, because it presents different behaviors. The first stage

ranged from 1 to 7 days, while the second stage was conducted

from 8 to 91 days.

The Table 5 shows the evolution of the resistance compression in

the first 7 days, when the samples were conditioned to a controlled

cure at low temperatures, ranging from 0° to 25 °C at 5 °C.

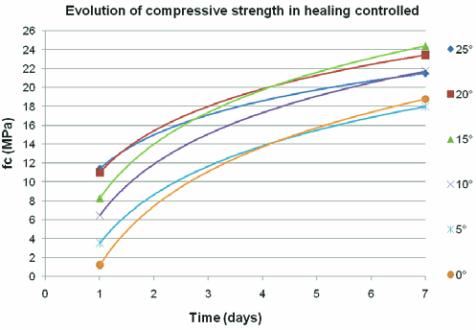

For better viewing, it was presented the results in Figure 1, relat-

ing the resistance compression in MPa, in the ‘y’ axis at the age of

rupture of the samples of the trial in ‘x’ axis, in days.

In this first period of curing it can be observed a greater variation of

resistance in the first day of measurement, which was 11.4 MPa for a

temperature of 25 °C and at 1.2 MPa for a temperature of 0 °C. The

higher curing temperatures presented superior outcomes of resistance

to compression and the resistance was gradually decreased to the low-

est temperature with the worst performance, as might be expected.

On the seventh day this variation was 24.4 MPa for a tempera-

ture of 15 °C and at 18 MPa for a temperature of 5 °C. The dif-

ference between the highest and lowest value decreased 37.25%

compared to the first period. That is, in the 7 days of curing, the

influence of initial curing temperatures have been lower, reach-

ing even to overlap different curves. Although the resistance gain

was more significant for cured concretes at lower temperatures,

approaching the cured concrete resistance at 0 °C increased about

1,600% between the 1st and 7th day, compared to a gain of 88%

of the cured at 25 °C.

Table 6 shows the evolution of resistance from 14 to 91 days of

curing. It is also illustrated in Figure 2, the results in chart form, for

better viewing.

In the second period of cure it is observed the approximation of

the results from day 7, the inversion in resistance values occurring

Table 4 – Weather conditions and

temperature of the molding

Moldings

Time and temperature of cure

0 a 7 days 8 a 91 days

1ª

25° C

20° C

2ª

20° C

20° C

3ª

15° C

20° C

4ª

10° C

20° C

5ª

5° C

20° C

6ª

0° C

20° C

Table 5 – Evolution of compressive

strength in healing controlled

Compressive strength

°C

1 day

7 days

(MPa)

(MPa)

25

11,4

21,5

20

11

23,4

15

8,3

24,4

10

6,5

21,7

5

3,5

18

0

1,2

18,8

Table 6 – Evolution of resistance to

compression in air-conditioned room (20º C)

Compressive strength

°C

14 days

28 days

91 days

(MPa)

(MPa)

(MPa)

25

24,3

26,9

29,2

20

27,5

31

31,4

15

28,7

21,7

27,8

10

27,3

31,8

28,7

5

20,9

35,6

37,6

0

30,3

38,6

38,8

Figure 1 – Evolution of compressive strength

in the first 7 days in controlled healing