Basic HTML Version

22

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 1

Steel fibre reinforced concrete pipes. Part 2: Numerical model to simulate the crushing test

which lately is losing its market share in favor of the plastic pipes.

Therefore, new alternatives and improvements are necessary for

the concrete pipe to be competitive once again (Viñolas

et al

. [1]).

For the analysis, a range of

C

f

between 0 kg/m

3

and 30 kg/m

3

was

established. The first amount would correspond to an unreinforced

concrete pipe (UCP), and the second one has been established as

a maximum value because of economic criteria.

Likewise, the requirement of a minimum early compressive

strength is necessary for demolding and to manipulate the pipe. In

order to satisfy this requirement an

f

ck

of 45 MPa at age of 28 days

has been assumed in order to carry out the analysis.

Table 3

presents the values for the mechanical parameters used

to simulate the tension behavior of SFRC.

The values of

F

c

and

F

u

fixed in NBR 8890:2007 for the strength

classes EA2, EA3 and EA4 for pipes with

D

i

= 400 mm are gath-

ered in the

Table 4

.

Table 4 – Design loads for each strength class

for pipes with D = 400 mm

i

EA2

EA3

EA4

F (kN)

c

60

90

120

F (kN)

u

90

135

180

F (kN)

min,pos

63

94.5

126

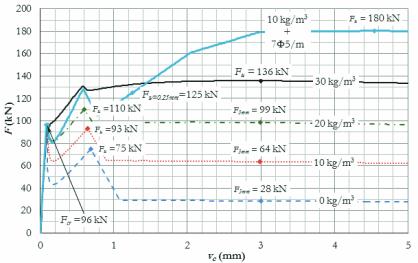

Figure 7 – F-v curves for the pipes with D = 400 mm and different reinforcement configurations

c

i

Fig. 7 shows the curves

F

-

v

c

obtained with the MAP model. From

those curves, it is deduced that:

n

The load

F

cr

obtained in the four cases (96 kN) is enough to

reach the load

F

c

stipulated in classes EA2 (60 kN) and EA3

(90 kN). However, the value of

F

c

for class EA4 (120 kN) can-

not be reached by means of the addition of metallic fibres only

(stress

σ

1

is independent from

C

f

).

n

The 90 kN established for

F

u

in class EA2 are exceeded if a

fibre dosage of 10 kg/m

3

(93 kN) is used. But, in order to reach

the 135 kN stipulated for class EA3, according to the numerical

model, at least 30 kg/m

3

of fibres (136 kN) are required. On the

other hand, the

C

f

necessary to achieve the 180 kN established

for class EA4 is not under the economically competitive values.

n

In order to reach the 63 kN specified for the

F

min,pos

of classEA2

and the 94.5 kN of class EA3, 10 kg/m

3

(64 kN) and 20 kg/m

3

(99 kN) are required, respectively.

Therefore, keeping in mind that the three strength requirements

must be fulfilled simultaneously for a fixed

C

f

, it is possible to con-

clude that 10 kg/m

3

of fibres would be required to achieve the EA2

class requirements, and 30 kg/m

3

would be required for class EA3,

according to the numerical model.

Alternatively, in order to achieve class EA4 with an economically

attractive reinforcement configuration, a composite solution could

be proposed (fibres + bars). On one hand, the load

F

c

(

F

w

=0.25mm

in

case of SBFRCP) would be reached thanks to the use of fibres.

On the other hand, the steel bars would guarantee higher failure

strength due to their higher efficiency and strategic position within

the section.